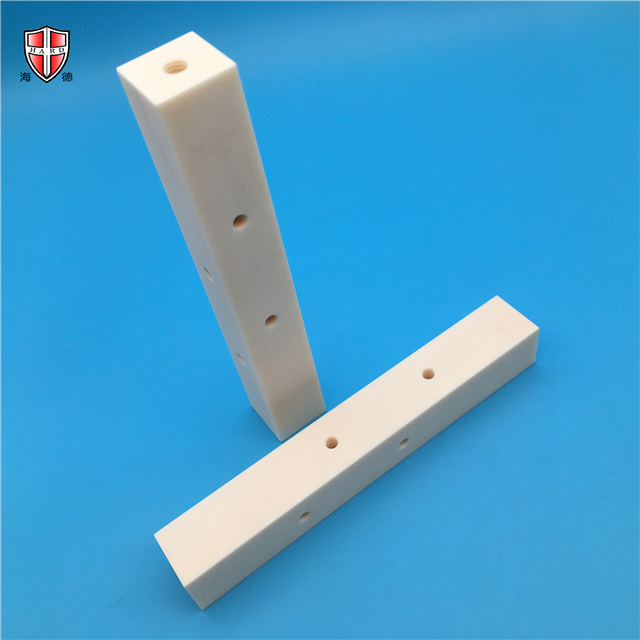

99.5 alsint Alumina Ceramic grinding drilling long bar

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

With the rapid development of aviation and aerospace technology, the requirements of various components in the aircraft and spacecraft of Alumina ceramics have been continuously improved, which has made the application of PC in this field increasingly increased. According to statistics, there are 2500 polycarbonate components used on a Boeing aircraft alone, and a single plane consumes about 2 tons of polycarbonate. On the spacecraft, hundreds of polycarbonate components with different configurations and reinforced by glass fiber and astronaut protective equipment are used. The new growth point in the packaging field is various types of water storage bottles that can be repeatedly sterilized and used. Because polycarbonate products have the advantages of light weight, good impact resistance and transparency, no deformation and transparency when washed with hot water and corrosive solutions, PC bottles have completely replaced glass bottles in some areas. It is predicted that as people pay more attention to drinking water quality, the growth rate of polycarbonate consumption in this area will remain above 10%, and it is expected to reach 60,000 tons by 2005. Since polycarbonate has good and constant electrical insulation in a wide range of temperature and humidity, it is an excellent insulating material. At the same time, its good flame retardancy and dimensional stability make it form a broad application field in the electronic and electrical industry. Polycarbonate resin is mainly used in the production of various food processing machinery, power tool housings, bodies, brackets, refrigerator freezer drawers and vacuum cleaner parts. And for the important parts of computers, video recorders and color TVs that require high parts accuracy, polycarbonate materials also show extremely high use value.

properties: High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/Ivory Density: 3.9g/cm3 Alumina Content: 96% 99% 99.5% Gas permeability: 0 Water Absorption: 0 MONS' Hardness: 82 Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²) Flexural Strength(20°C): 330Mpa Compressive Strength(20°C): 2000Mpa Fracture Toughness (20°C): 4 MPam1/2 Thermal Conductivity(20°C): 27.5W(m.K) Thermal Expansion Coefficient: 7.6 10-6/°C Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Application industry: Machinery, electronic, chemical, petroleum etc. Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.