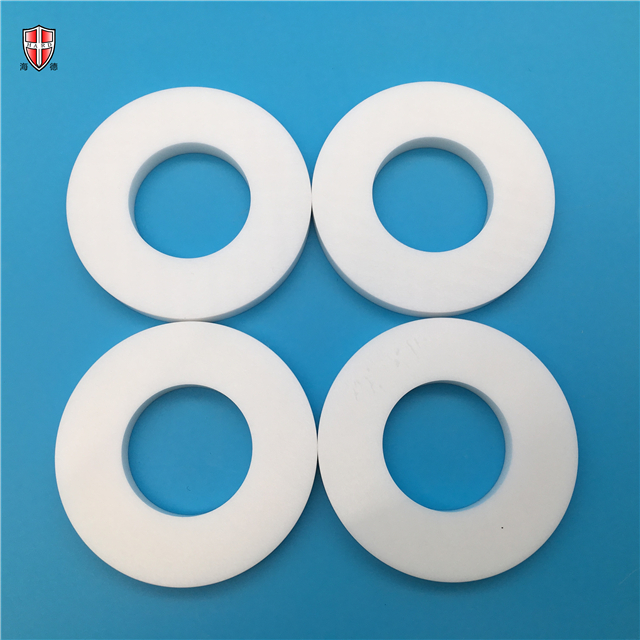

advanced Alumina Ceramic Material spacer sealing ring

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

Temperature range of the tendency of alumina ceramics to transform into inclined pyroxene or refractory pyroxene at 1042 ° C. Properly increasing the cooling rate can reduce this tendency of crystal-plastic conversion, avoid glass phase crystallization, and fully utilize glass phase wrapping The effect of the original refractory and inhibiting the transformation of its Ceramic Plunger crystal form has a certain effect on preventing the aging of talc porcelain. Research and practice have shown that strict formula design and selection of raw materials and optimization of process conditions are important measures to prevent or avoid aging of talc porcelain. One of the prone quality problems of talc porcelain is cracking, which causes product scrap. This is often caused by the extrusion or molding of talc porcelain and improper processing of talc raw materials. The Alumina Zirconia talc raw material is anisotropic. When used directly in batching and molding, this talc powder tends to have smaller flakes. The directional arrangement is formed during molding, which results in the molding blanks also being individually anisotropic. When stress occurs during the firing process, cracks or cracks appear on the porcelain and become waste products. Although some cracks or cracks appear on some porcelain, the mechanical strength of the porcelain decreases due to the greater stress in the porcelain. Affects the actual use of porcelain. In order to prevent this kind of quality problem, the main measures taken in production are pre-calcining the talc raw material to destroy the layered structure of the talc raw material. Then it is ground. The talc raw material with granular structure is used in the production of talc porcelain after grinding. The main crystalline phase is the original refractory ceramics, which uses talc as the main raw material, and Industrial Ceramic adds appropriate amounts of clay, bentonite and barium carbonate to high-temperature sintered ceramic materials. It has high strength and low dielectric loss. Used for high-frequency device parts, small-capacity high-power capacitors, and fine-tuned ceramic dielectric heaters.

properties: High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/Ivory Density: 3.9g/cm3 Alumina Content: 96% 99% 99.5% Gas permeability: 0 Water Absorption: 0 MONS' Hardness: 82 Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²) Flexural Strength(20°C): 330Mpa Compressive Strength(20°C): 2000Mpa Fracture Toughness (20°C): 4 MPam1/2 Thermal Conductivity(20°C): 27.5W(m.K) Thermal Expansion Coefficient: 7.6 10-6/°C Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Application industry: Machinery, electronic, chemical, petroleum etc. Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.