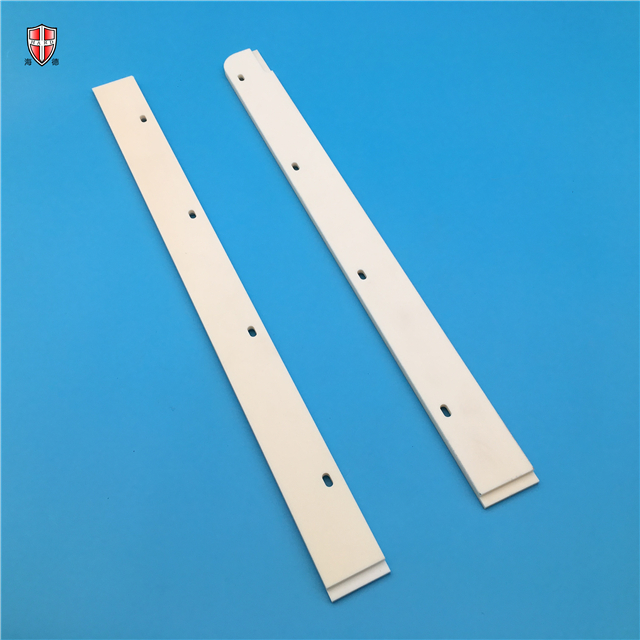

high temperature industry 99 99.5 Alumina Ceramic strip

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

Alumina ceramics are processes in which nitrogen atoms are infiltrated into the surface layer of steel, and the purpose thereof is to improve surface hardness and wear resistance, as well as to improve fatigue strength and corrosion resistance.

The alumina ceramic utilizes ammonia gas to decompose the active nitrogen atom upon heating, and is absorbed by the steel to form a nitride layer on the surface thereof, and simultaneously diffuses toward the core.

Alumina ceramics are usually carried out using specialized equipment or a well type carburizing furnace. Applicable to all kinds of high-speed transmission precision gears, machine tool spindles (such as masts, grinding machine spindles), high-speed diesel engine crankshafts, valves, etc.

Alumina ceramic workpiece process route: forging - annealing - roughing - quenching - finishing - stress removal - rough grinding - nitriding - fine grinding or grinding.

Since the nitrided layer is thin and brittle, it requires a higher strength of the core structure, so the tempering heat treatment is first performed to obtain the tempered sorbite, and the mechanical properties of the core and the quality of the nitrided layer are improved.

After nitriding, the steel no longer needs to be quenched to have a high surface hardness greater than HV850) and wear resistance.

The nitriding treatment has a low temperature and a small deformation, and the deformation is much smaller than that of carburizing and induction surface quenching.

Carbonitriding of steel: Carbonitriding is a process of simultaneously infiltrating carbon and nitrogen into the surface of steel. It is customary for carbonitriding to be called cyanidation. At present, the application of medium temperature gas carbonitriding and low temperature gas carbonitriding (ie gas nitrocarburizing) is widely used. The main purpose of carbonitriding of medium temperature gas is to improve the hardness, wear resistance and fatigue strength of steel. The low temperature gas carbonitriding is mainly nitriding, and its main purpose is to improve the wear resistance and seizure resistance of steel.

Therefore, in general, the high-viscosity pump is required to transport the non-lubricating and high-viscosity material. The high-viscosity pump gear must be nitrided to increase the surface hardness and wear resistance of the gear to prolong the service life of the high-viscosity pump.

properties: High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/Ivory Density: 3.9g/cm3 Alumina Content: 96% 99% 99.5% Gas permeability: 0 Water Absorption: 0 MONS' Hardness: 82 Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²) Flexural Strength(20°C): 330Mpa Compressive Strength(20°C): 2000Mpa Fracture Toughness (20°C): 4 MPam1/2 Thermal Conductivity(20°C): 27.5W(m.K) Thermal Expansion Coefficient: 7.6 10-6/°C Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Application industry: Machinery, electronic, chemical, petroleum etc. Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.