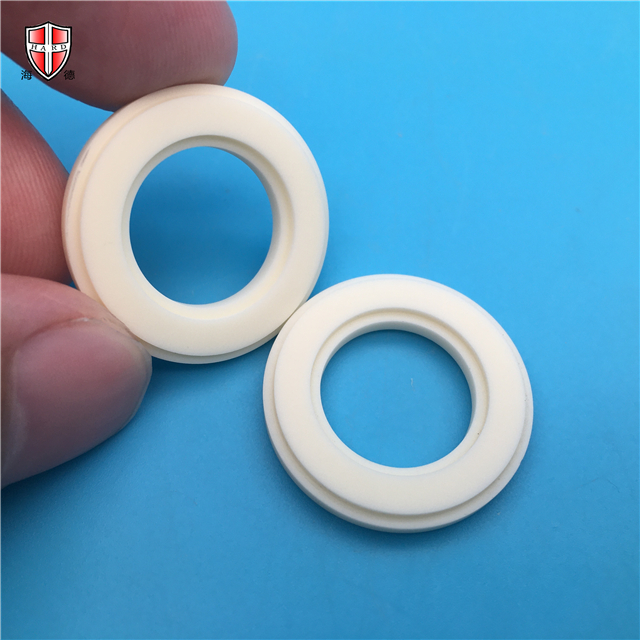

wearable 99% 99.5% Alumina Ceramic spacer washer

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

Alumina ceramic polyethylene (PE for short) is a thermoplastic resin made by polymerization of ethylene. In industry, it also includes copolymers of ethylene and a small amount of α-olefin. Polyethylene is odorless, non-toxic, feels like wax, has excellent low temperature resistance (the minimum use temperature can reach -100~-70°C), has good chemical stability, and can withstand most acid and alkali corrosion (not resistant to oxidation Nature of acid). It is insoluble in general solvents at room temperature, has low water absorption and excellent electrical insulation. On October 27, 2017, the list of carcinogens announced by the International Agency for Research on Cancer of the World Health Organization was initially compiled for reference. Polyethylene was included in the list of three types of carcinogens. Polyethylene was synthesized by British ICI Company in 1922. In 1933, British Benemen Chemical Industry Company discovered that ethylene can be polymerized to form polyethylene under high pressure. This method was industrialized in 1939 and is commonly known as the high-pressure method. In 1953, K. Ziegler of the Federal Republic of Germany discovered that with TiCl4-Al(C2H5)3 as a catalyst, ethylene can also be polymerized under lower pressure. This method was put into industrial production by the Federal German Hearst Company in 1955 and is commonly known as low-pressure polyethylene. In the early 1950s, the American Philips Petroleum Company discovered that using chromium oxide-alumina gel as a catalyst, ethylene could be polymerized to produce high-density polyethylene under medium pressure, and industrial production was realized in 1957. In the 1960s, DuPont of Canada began to manufacture low-density polyethylene with ethylene and α-olefin solution method. In 1977, Union Carbide and The Dow Chemical Company used low-pressure methods to make low-density polyethylene, called linear low-density polyethylene. Among them, the gas phase method of Union Carbide is the most important. The performance of linear low-density polyethylene is similar to that of low-density polyethylene, but it also has several characteristics of high-density polyethylene. In addition, it has low energy consumption in production, so it develops extremely rapidly and becomes one of the most eye-catching new synthetic resins.

properties: High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/Ivory Density: 3.9g/cm3 Alumina Content: 96% 99% 99.5% Gas permeability: 0 Water Absorption: 0 MONS' Hardness: 82 Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²) Flexural Strength(20°C): 330Mpa Compressive Strength(20°C): 2000Mpa Fracture Toughness (20°C): 4 MPam1/2 Thermal Conductivity(20°C): 27.5W(m.K) Thermal Expansion Coefficient: 7.6 10-6/°C Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Application industry: Machinery, electronic, chemical, petroleum etc. Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.