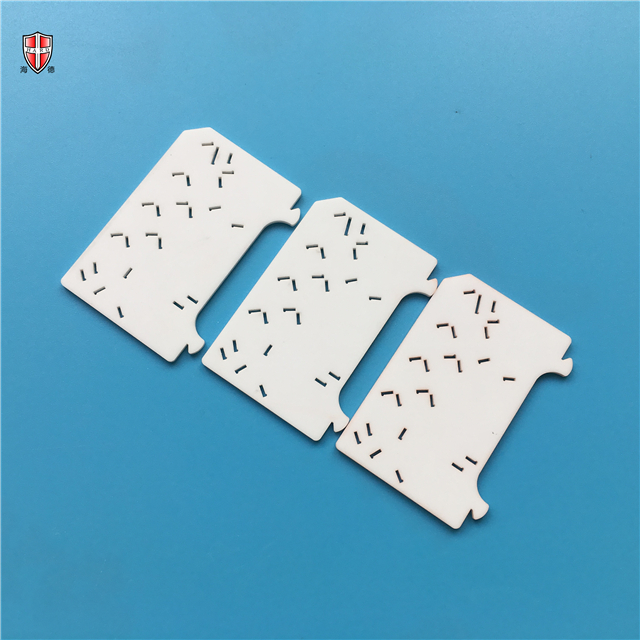

high thermal conductivity Alumina Ceramic Substrate chip

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

99.70% corundum 1800 ° C 1650 ° C -1700 ° C corundum in the oxidation and reducing atmosphere, has good high temperature insulation and mechanical strength. The thermal conductivity is large and the thermal expansion rate is small. It does not react with air, water vapor, hydrogen, carbon monoxide or the like above 1700 °C. The short-term maximum operating temperature is 1800 °C. 99.35% corundum 1750 ° C 1600 ° C - 1650 ° C corundum in the oxidation and reduction atmosphere. 85.00% high aluminum 1350 ° C 1290 ° C high aluminum crucible in the oxidation and reducing atmosphere, has good high temperature insulation and mechanical strength. The thermal conductivity is large and the thermal expansion rate is small. Does not react with air, water vapor, hydrogen, carbon monoxide, etc. It can be used for a long time when the temperature of the temperature field does not change much. The short-term maximum operating temperature is 1400 °C. The raw materials for production can be summarized into three major types. One is crystalline natural graphite, the other is plastic refractory clay, and the third is calcined hard kaolin skeleton clinker. Since 2008, high-temperature resistant synthetic materials such as silicon carbide, alumina silicon carbide and ferrosilicon have been used as skeleton skeleton clinker. This clinker has a significant effect on improving the quality of niobium products, enhancing tantalum density and mechanical strength. Quartz crucible can be used below 1650 degrees, both transparent and opaque. The translucent quartz crucible made by the arc method is a large-diameter single crystal silicon, which is an indispensable basic material for the development of large-scale integrated circuits. Today, the world's semiconductor industry developed countries have used this to replace small transparent quartz crucibles. It has the advantages of high purity, high temperature resistance, large size, high precision, good heat preservation, energy saving and stable quality.

properties: High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/Ivory Density: 3.9g/cm3 Alumina Content: 96% 99% 99.5% Gas permeability: 0 Water Absorption: 0 MONS' Hardness: 82 Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²) Flexural Strength(20°C): 330Mpa Compressive Strength(20°C): 2000Mpa Fracture Toughness (20°C): 4 MPam1/2 Thermal Conductivity(20°C): 27.5W(m.K) Thermal Expansion Coefficient: 7.6 10-6/°C Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Application industry: Machinery, electronic, chemical, petroleum etc. Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.