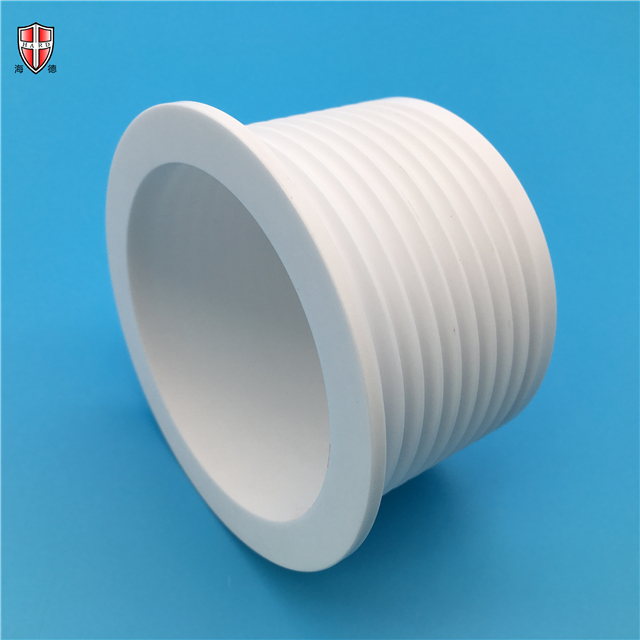

cnc machining 95% alumina Al2O3 Ceramic cavity nut

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

The working principle of alumina rotary kiln. The calcined alumina powder is input into the tail end of the kiln body with a certain inclination and slow rotation (the high end of the cylinder), and the kiln head cover from the kiln head (lower end of the cylinder) is sprayed with a spray gun The clean flame is sprayed into the kiln, and the alumina powder is dehydrated and calcined. After being dehydrated at a high temperature of about 1650 ° C, the calcined alumina powder is tumbling in the circumferential direction and in the axial direction by means of the inclined rotary kiln body. Move from high-end to low-end, gradually complete the dehydration and calcination process, enter the cooling machine through the flap discharge valve in the lower part of the kiln cover, and the cooled and sieved material is the high-temperature alumina finished product. Calcined alumina rotary kiln production line equipment is popular in Henan manufacturers. The powder used for metal mirror polishing is classified into alumina and silica. Silica is generally used for the mirror treatment of aluminum alloys due to its low Mohs hardness and low particle size, and it does not provide sufficient cutting force for cousin treatment such as stainless steel or iron. Therefore, the mirror surface treatment of the metal surface is mainly based on alumina.

properties: High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/Ivory Density: 3.9g/cm3 Alumina Content: 96% 99% 99.5% Gas permeability: 0 Water Absorption: 0 MONS' Hardness: 82 Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²) Flexural Strength(20°C): 330Mpa Compressive Strength(20°C): 2000Mpa Fracture Toughness (20°C): 4 MPam1/2 Thermal Conductivity(20°C): 27.5W(m.K) Thermal Expansion Coefficient: 7.6 10-6/°C Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Application industry: Machinery, electronic, chemical, petroleum etc. Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.