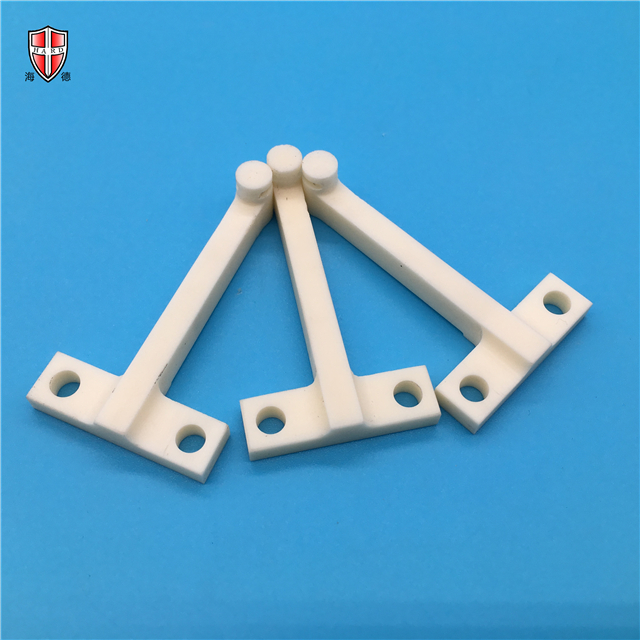

cnc wearable Alumina Ceramic machinery spare parts

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

The alumina direct copper coating technology uses copper oxygen-containing eutectic liquid to directly apply copper to the ceramic. The basic principle is to introduce an appropriate amount of oxygen between copper and ceramic before or during the bonding process, at 1065 ° C ~ 1083 In the range of °C, copper and oxygen form a Cu-O eutectic liquid. The DBC technology uses the eutectic liquid to chemically react with the ceramic substrate to form a CuAlO2 or CuAl2O4 phase, and on the other hand, infiltrate the copper foil to realize the combination of the ceramic substrate and the copper plate.

◆The thermal expansion coefficient of the ceramic substrate is close to that of the silicon chip, which can save the transition layer Mo film, save labor, material and reduce cost;

◆Reduce the solder layer, reduce the thermal resistance, reduce the void, and improve the yield;

◆ The line width of 0.3mm thick copper foil is only 10% of ordinary printed circuit board under the same current carrying capacity;

◆ Excellent thermal conductivity, which makes the chip package very compact, which greatly increases the power density and improves the reliability of the system and device;

◆ Ultra-thin (0.25mm) ceramic substrate can replace BeO, no environmental toxicity problem;

◆The current carrying capacity is large, 100A current continuously passes through the 1mm wide and 0.3mm thick copper body, and the temperature rise is about 17°C; the 100A current continuously passes through the 2mm wide and 0.3mm thick copper body, and the temperature rise is only about 5°C;

◆The thermal resistance is low, the thermal resistance of the 10×10mm ceramic substrate is 0.63mm, the thermal resistance of the ceramic substrate is 0.31K/W, the thermal resistance of the 0.38mm thick ceramic substrate is 0.19K/W, and the thickness of the 0.25mm ceramic substrate The thermal resistance is 0.14K/W.

◆ High insulation withstand voltage to ensure personal safety and equipment protection.

◆ New packaging and assembly methods can be implemented to make the product highly integrated and compact.

properties: High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/Ivory Density: 3.9g/cm3 Alumina Content: 96% 99% 99.5% Gas permeability: 0 Water Absorption: 0 MONS' Hardness: 82 Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²) Flexural Strength(20°C): 330Mpa Compressive Strength(20°C): 2000Mpa Fracture Toughness (20°C): 4 MPam1/2 Thermal Conductivity(20°C): 27.5W(m.K) Thermal Expansion Coefficient: 7.6 10-6/°C Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Application industry: Machinery, electronic, chemical, petroleum etc. Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.