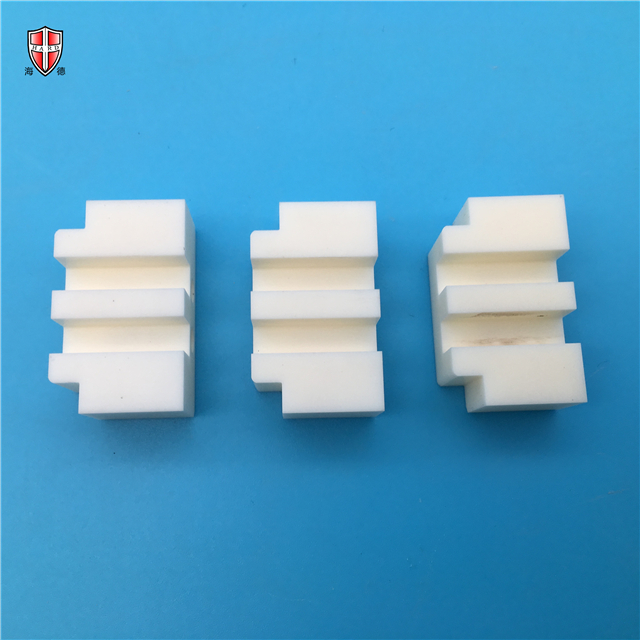

custom technical Alumina Ceramic machined parts

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

Pottery can be made from ordinary clay and fired. Porcelain needs to choose specific materials to be made from kaolin. The firing temperature can become pottery at the required temperature stage of pottery, such as ancient white pottery. At the temperature required for firing kaolin, the green body is made into porcelain. However, when the body made of clay made of pottery is generally 1200 ° C, it is impossible to become porcelain and it will be fused to glass. Even if the body of the pottery is thin, it is not translucent. For example, the black pottery of Longshan culture is as thin as an eggshell, but it is not transparent. Regardless of its thickness, porcelain carcasses are translucent. There are two types of pottery: unglazed and hanging glaze. The glaze of the pottery can be melted at a lower firing temperature. There are two kinds of glazes for porcelain, which can be fired with the carcass at high temperature once, or can be hung with low-temperature glaze on high-temperature plain fired tires, and fired for the second time at low temperature. Porcelain was also called kiln in ancient times. Porcelain is made of porcelain clay (porcelain stone) as raw material. After being shaped, dried and glazed, it is fired at a high temperature of about 1300oC. The appearance is hard and dense, the surface is smooth and clean, the colloid is thin and translucent, the sound is clear when tapped, and does not absorb water.

1. The raw material of pottery is clay. Clay is preferable everywhere and is not restricted by geographical conditions.

2, pottery firing temperature is generally lower than 800 degrees Celsius.

3. The density of the pottery is small and the water absorption rate is high.

4. Pottery is generally composed of pottery tires only.

properties: High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/Ivory Density: 3.9g/cm3 Alumina Content: 96% 99% 99.5% Gas permeability: 0 Water Absorption: 0 MONS' Hardness: 82 Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²) Flexural Strength(20°C): 330Mpa Compressive Strength(20°C): 2000Mpa Fracture Toughness (20°C): 4 MPam1/2 Thermal Conductivity(20°C): 27.5W(m.K) Thermal Expansion Coefficient: 7.6 10-6/°C Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Application industry: Machinery, electronic, chemical, petroleum etc. Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.