high heat conductivity 95% 99% aluminum oxide ceramics

Reputation depends on quality, quality comes from Hard!

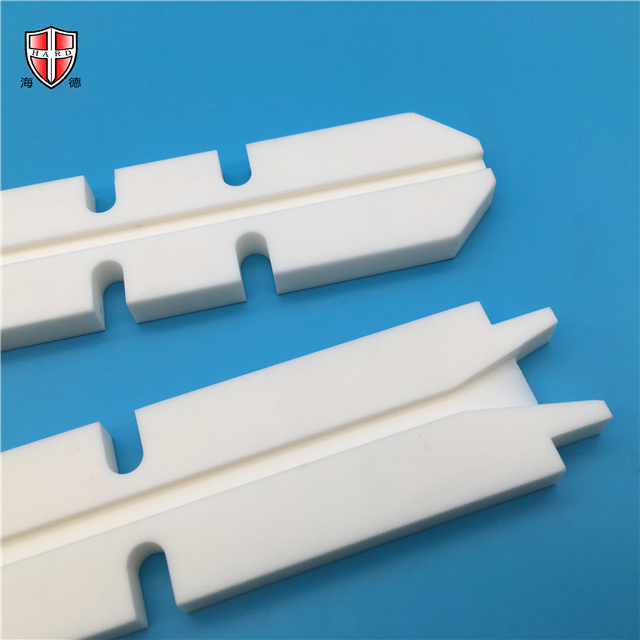

Alumina Ceramics:

Stabilizers mainly refer to agents that maintain the stability of polymer plastics, rubber, synthetic fibers, etc., and prevent their decomposition and aging. In order to prevent the synthetic resin from being decomposed and damaged by light and heat during processing and use, and to extend its service life, stabilizers must be added to the plastic. Commonly used are stearate and epoxy resin. The amount of stabilizer is generally 0.3 to 0.5% of the plastic. The colorant can make the plastic have various bright and beautiful colors. Commonly used organic dyes and inorganic pigments as colorants. The natural color of synthetic resin is mostly white translucent or colorless and transparent. Colorants are often used in industrial production to increase the color of plastic products. The function of the lubricant is to prevent the plastic from sticking to the metal mold during molding, and to make the surface of the plastic smooth and beautiful. Commonly used lubricants include stearic acid and its calcium and magnesium salts. Prevent the plastic from being heated and oxidized during heat molding or high-temperature use, which will cause the plastic to turn yellow and crack. In addition to the above additives, flame retardants, foaming agents, antistatic agents, conductive agents, magnetic permeability agents, compatibilizers, etc. can also be added to the plastic. To meet different requirements. Plastics are excellent insulators, so they are easily charged with static electricity. Antistatic agents can impart mild to moderate electrical conductivity to plastics, thereby preventing the accumulation of static charges on the products. Generally refers to plastics with large output, wide use, good formability and low price. There are five types of general plastics, namely polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS) and acrylonitrile-butadiene-styrene copolymer (ABS). These five types of plastics account for the vast majority of plastic raw materials, and the rest can basically be classified into special plastic varieties, such as: PPS, PPO, PA, PC, POM, etc., they are used in daily life products very little, mainly It is applied in high-end fields such as engineering industry, national defense technology, etc., such as automobile, aerospace, construction, communication and other fields. Plastics are classified according to their plasticity and can be divided into thermoplastics and thermosetting plastics.

properties: High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/Ivory Density: 3.9g/cm3 Alumina Content: 96% 99% 99.5% Gas permeability: 0 Water Absorption: 0 MONS' Hardness: 82 Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²) Flexural Strength(20°C): 330Mpa Compressive Strength(20°C): 2000Mpa Fracture Toughness (20°C): 4 MPam1/2 Thermal Conductivity(20°C): 27.5W(m.K) Thermal Expansion Coefficient: 7.6 10-6/°C Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Application industry: Machinery, electronic, chemical, petroleum etc. Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.