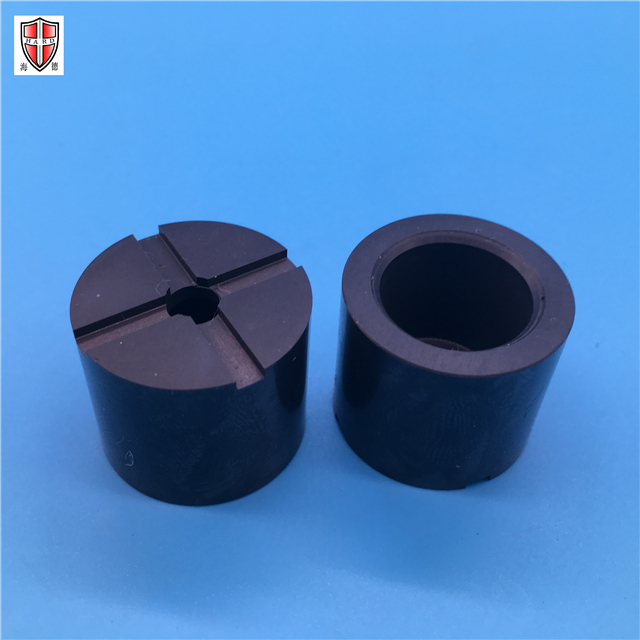

insulating Si3N4 ceramic tube oil cup mug

Reputation depends on quality, quality comes from Hard!

Silicon Nitride Ceramic:

Due to different preparation processes, various types of Silicon Nitride Ceramics have different microstructures (such as porosity and pore morphology, grain morphology, intergranular morphology, and intercrystalline second phase content). In order to obtain Si3N4 ceramic materials with excellent performance, high-quality Si3N4 powder should be prepared first. The quality of Si3N4 powder prepared by different methods is not exactly the same, which leads to the difference in its application. The failure of many ceramic materials is often attributed to Developers do not understand the difference between various ceramic powders, and have insufficient understanding of their properties. Generally speaking, high-quality Si3N4 powder should have high α phase content, uniform composition, less impurities and uniform distribution in ceramics, and small particle size. The α phase of the Si3N4 powder with good particle size distribution and good dispersion is at least 90%. This is because during the sintering process, some α phase will change into β phase, but there is not enough α phase content. Will reduce the strength of ceramic materials. At present, China's large and medium-sized ceramic abrasives production backbone enterprises, mainly in the use of hierarchical furnaces, or is gradually upgrading the level of the furnace, these enterprises include the original The state-owned large and medium-sized backbone enterprises, the reformed joint-stock enterprises, foreign-funded enterprises and joint ventures, and some private enterprises developed this year, the number of enterprises is mainly located in coastal areas, Jiangsu, Zhejiang and domestic large and medium-sized cities. In the 1000-3000 tons or more, its product varieties have certain characteristics, can produce high-end products, and some products have reached the level of similar foreign high-quality products. These enterprises are the mainstream enterprises of China's ceramic abrasives production, and many other small and medium-sized enterprises. The third level of kiln, some of which have or are gradually being transformed into the second level of kiln, which uses a small ejector direct-fired drawer kiln, many of these enterprises are distributed throughout the country.

properties:

High hardness, high strength, wear resistance, corrosion resistance, high temperature(1200°), good thermal diffusivity, good thermal shock resistance(avoid the temperature changing rapidly), good insulativity, low density. The comprehensive properties are best in most of structure ceramic.

Data Sheet↓

Color: Black Grey

Density: >3.2g/cm3

Hardness: HRA90

Vickers Hardness (Hv50): >1550 HV0.5

Modulus of Elasticity: 290Gpa

Flexural Strength: >600Mpa

Compressive Strength: 2500Mpa

Modulus of Elasticity(25°C): 65Gpa

Fracture toughness:>6.0 Mpam1/2

Maximum Use Temperature: 1200°C

Thermal Conductivity:15-20 W(m.K)

Thermal Expansion Coefficient: >3.1 10-6/°C

Thermal Shock Resistance: 500 △T°C

Special Heat Capacity: 700 KJ/kg.K

Dielectric Strength: 1 KV/mm

Dielectric Constant: er

Volume Resistivity(20°C): 1.0*10(12)Ω.cm

Application industry:

Machinery, electronic, semiconductor, chemical, petroleum, smelt.

Specific application:

Welding shaft, electronic substrate, plunger, nozzle, slide guide, diesel parts, metal molding, shaft wheels etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.