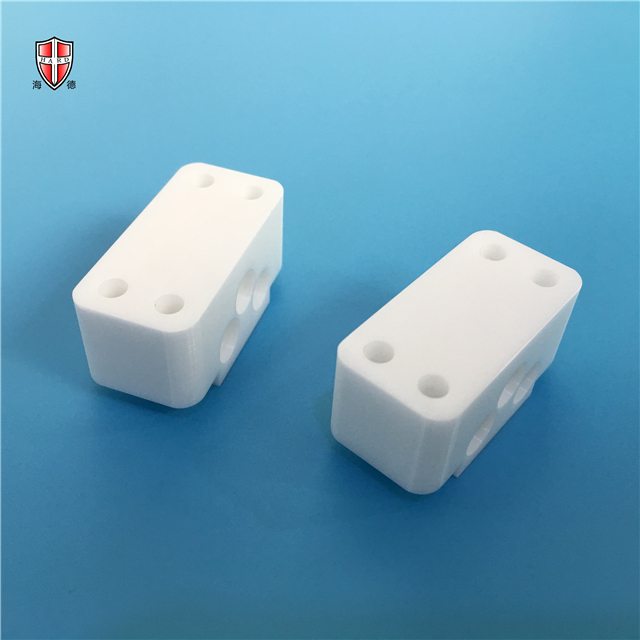

high precision Zirconia Ceramic structural components

Reputation depends on quality, quality comes from Hard!

Zirocnia Ceramics:

Zirconium dioxide (ZrO2) is a high melting point metal oxide having a relative molecular weight of 123.22, a boiling point of 4300 ° C, a softening point in the range of 2390 ° C to 2500 ° C, and a melting point of 2715 ° C. Zirconium dioxide is insoluble in water, sulfuric acid, hydrochloric acid and nitric acid, and is slightly soluble in hydrofluoric acid and concentrated sulfuric acid when heated. Pure zirconia is white and the purer zirconia is pale yellow. Pure zirconium dioxide is an insulator at normal temperature, and the addition of a stabilizer can increase its conductivity and exhibit ionic conductivity at high temperatures. The three crystal forms of zirconium dioxide can be converted into each other with changes in temperature: above 1170 ° C, the monoclinic phase will be converted into a tetragonal phase; when it exceeds 2370 ° C, the tetragonal phase will be converted into a cubic phase. Generally, ceramic materials are relatively brittle and hard, but Zirconia Ceramics are special because of the higher toughness due to the transition between the tetragonal phase and the monoclinic phase described above. This phase changes to martensite transformation and is characterized by the following:

a, nucleation of the growth process, t-m phase change without diffusion, in a very high temperature range, the atom is ordered displacement, but the displacement is less than one atomic spacing, adjacent atoms remain adjacent after the phase change;

b, t-m phase transition is accompanied by large volume change (3%-5%) and shear strain (1%-7%), and the phase change is reversible, and m-t phase change occurs when heated;

c. The t-m phase transition temperature is determined by the grain size and the external force. The finer the phase, the lower the phase transition temperature. When the external pressure is higher than 3700 MPa, the tetragonal zirconia can be kept to room temperature.

Data Sheet↓

Color: Customized Density: 6.0g/cm3 Zirconia Content: 94.4% Gas permeability: 0 Water Absorption: 0 Crystal Size: 0.5um Rockwell Hardness(45N): 78R45N Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²) Flexural Strength(20°C): 800Mpa Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Fracture Toughness(20°C): 9.0 MPam1/2 Thermal Conductivity(20°C-400°C): 2.5W(m.K) Thermal Expansion Coefficient: 9.6 10-6/°C Thermal Shock Resistance: 250 △T°C

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, Ceramic Shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.