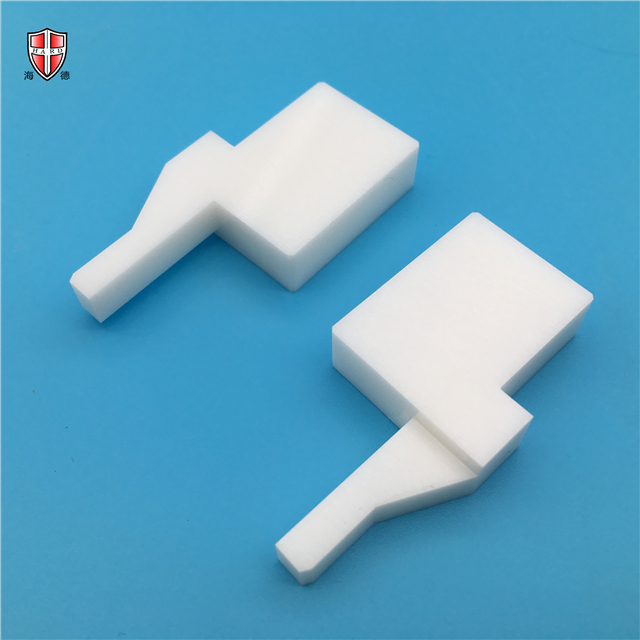

hard custom made Zirconia Ceramic Block brick tile

Reputation depends on quality, quality comes from Hard!

Zirconia Ceramics:

Zirconia sheet and thermoforming: The thermoforming lining of many large picnic refrigerators is made of PE, which is tough, light and durable. Other sheet and thermoformed products include mudguards, tank liners, pan guards, shipping boxes and tanks. A large number of fast-growing sheet applications are mulch or pond bottom villages, which are based on MDPE's toughness, chemical resistance, and impermeability.

Blow molding: More than 1/3 of HDPE sold in the United States is used for blow molding. These range from bottles containing bleach, motor oil, detergent, milk and distilled water to large refrigerators, car fuel tanks and canisters. The characteristics of blow molding grades, such as melt strength, ES-CR and toughness, are similar to those used for sheet and thermoforming applications, so similar grades can be used.

Injection-blow molding is usually used to make smaller containers (less than 16oz) for packaging medicines, shampoos and cosmetics. One of the advantages of this process is that the production bottles are automatically trimmed, without the need for post-finishing steps like general blow molding. Although some narrow MWD grades are used to improve surface finish, medium to wide MWD grades are generally used.

Rotational molding: The materials used in this processing method are generally crushed into powder materials, which are melted and flowed in a thermal cycle. Rotomolding uses two types of PE: general-purpose and cross-linkable. General-purpose MDPE/HDPE usually has a density ranging from 0.935 to 0.945g/CC, with a narrow MWD, which enables the product to have high impact and minimal warpage. Its melt index is generally in the range of 3-8. Higher MI grades are generally not suitable because they do not have the impact and environmental stress crack resistance expected of rotomolded products.

Film: PE film processing generally uses ordinary blown film processing or flat extrusion processing. Most PE is used for film, general low density PE (LDPE) or linear low density PE (LLDPE) are available. HDPE film grades are generally used where superior stretchability and excellent impermeability are required. For example, zirconia film is commonly used in commodity bags, grocery bags and food packaging.

Data Sheet↓

Color: Customized Density: 6.0g/cm3 Zirconia Content: 94.4% Gas permeability: 0 Water Absorption: 0 Crystal Size: 0.5um Rockwell Hardness(45N): 78R45N Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²) Flexural Strength(20°C): 800Mpa Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Fracture Toughness(20°C): 9.0 MPam1/2 Thermal Conductivity(20°C-400°C): 2.5W(m.K) Thermal Expansion Coefficient: 9.6 10-6/°C Thermal Shock Resistance: 250 △T°C

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, Ceramic Shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.