Y2O3 yttria stabilized black zirconia YTZP ceramics

Reputation depends on quality, quality comes from Hard!

Zirocnia Ceramics:

Zirconium dioxide has extensive use in high temperature structural materials, fuel cells and other fields due to its excellent mechanics, thermal, electrical and unique phase transition effects and high temperature oxygen ion conductivity. Black Zirconia Ceramic material has become a new type of high-grade decorative materials such as high-end home decoration crafts, watch bracelets, TV curtain wall decoration materials, etc. due to its excellent mechanical properties, pure color, metallic luster and low radiation. market expectation.

At present, the preparation of the black Zirconia Ceramic mainly adopts the following methods: (1) The zirconia ceramic is blackened by a vacuum atmosphere, a reducing atmosphere or an inert atmosphere. The method has strict requirements on equipment, high production cost, and difficulty in preparing black ceramic products with complicated shapes; (2) adding colored oxides such as iron, cobalt, chromium, titanium, manganese, etc. to the zirconia powder, and uniformly mixing the materials. , black zirconia ceramic is obtained by molding and sintering. The method is difficult to achieve uniform mixing of the color material and the zirconia, the preparation process is complicated, the content of the color material and the sintering temperature are strict, and the raw material cost is high, and there are potential problems such as heavy metal leakage and radiation.

In addition, in recent years, as people pay more and more attention to the ecological environment, the preparation process of materials requires low cost (sintering temperature is low, process is simplified, etc.), pollution-free, and the source of selection is as wide as possible.

1) Since the copper ion colorant and the zirconium atom are uniformly mixed at the atomic level in the solution, the problem of uneven coloration of the black zirconia is avoided.

2) Using simple copper ions as a coloring agent, avoiding the toxic effects of cobalt, chromium, titanium and manganese on the human body.

3) The precursor solution is arranged by a liquid phase method to uniformly mix the colored ions with the zirconium atom at an atomic level, and the precursor complex is further obtained by a coprecipitation method, and the black zirconia raw material powder is obtained by low temperature heat treatment.

4) The raw material powder has simple preparation process, low raw material cost, no pollution, strong operability, high activity of the obtained raw material powder, low sintering temperature, and overcomes high requirements on equipment and sintering temperature in the conventional preparation method. The preparation process is complicated and the production cost is high.

A fast, low-cost preparation method for a black zirconia ceramic is achieved by the following steps:

(1) Zr(OH)4 and CuNO3 were used as raw materials, and Zr(OH)4-CuNO3 precursor solution was prepared by using distilled water. The mass ratio of Zr(OH)4 to CuNO3 was 1:1.

(2) using ammonia water to adjust the pH of the precursor solution in step 1 to 9, and heating at 60 ° C in a constant temperature water bath for 1.5 hours to obtain a precursor complex;

(3) the precursor complex obtained in the step 2 is subjected to suction filtration, impurity removal, drying, and grinding to obtain a precursor powder;

(4) The precursor powder obtained in the step 3 is heat-treated at 600 ° C for 1 hour to obtain a black zirconia raw material powder;

(5) The black zirconia raw material powder obtained in the step 4 was subjected to a cold press molding, and then sintered at 900 ° C for 2 hours to obtain a black zirconia ceramic article.

Data Sheet↓

Color: Customized Density: 6.0g/cm3 Zirconia Content: 94.4% Gas permeability: 0 Water Absorption: 0 Crystal Size: 0.5um Rockwell Hardness(45N): 78R45N Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²) Flexural Strength(20°C): 800Mpa Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Fracture Toughness(20°C): 9.0 MPam1/2 Thermal Conductivity(20°C-400°C): 2.5W(m.K) Thermal Expansion Coefficient: 9.6 10-6/°C Thermal Shock Resistance: 250 △T°C

Application industry:

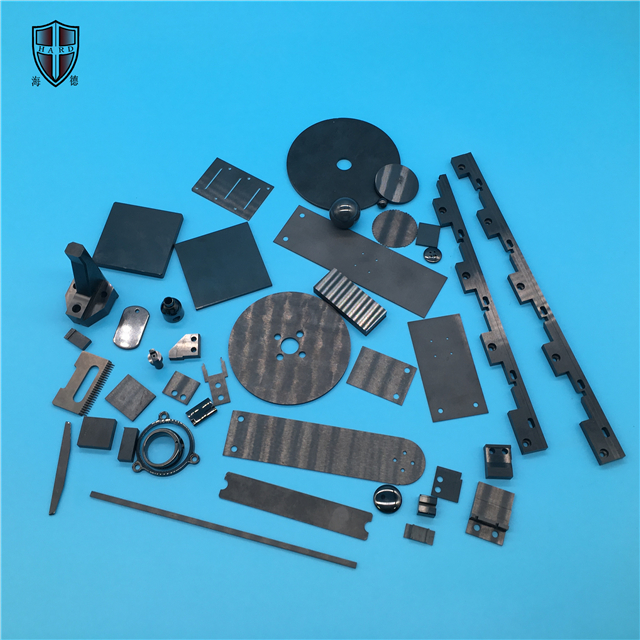

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, Ceramic Shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.