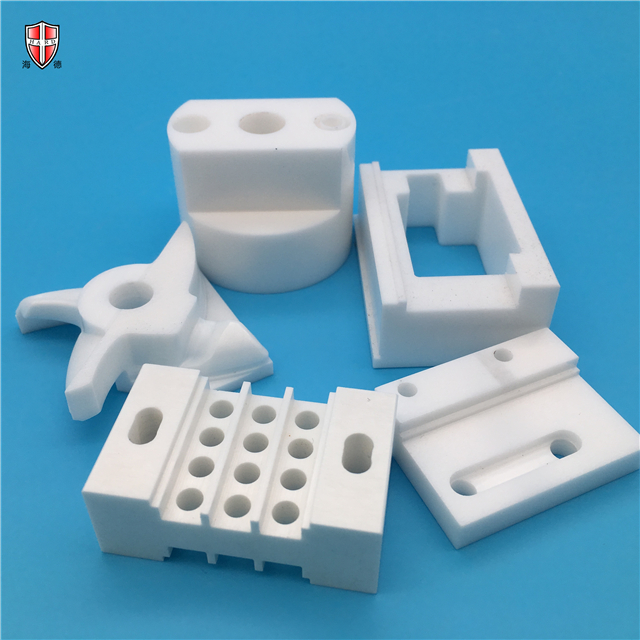

precision Zirconia Ceramic structural machining parts

Reputation depends on quality, quality comes from Hard!

Zirocnia Ceramics:

With the continuous advancement of processing technology and the increasing level of technology, the cost of ceramic bearings has been declining. From the past, it has only been applied in a small range of high, fine and pointed fields, and gradually extended to various industrial fields of the national economy. It is also approaching practicality and reaching a level acceptable to users. The wave of ceramic bearing applications has already arrived! (1) High-speed bearing: It has the advantages of cold resistance, small elasticity, high pressure resistance, poor thermal conductivity, light weight, small friction coefficient, etc. It can be applied to high speed spindles of 12000 rpm/-75000 rpm and others. High precision equipment;

(2), high temperature bearing: the material itself has a high temperature resistance of 1200 ° C, and self-lubricating, the use temperature does not produce expansion due to temperature difference between 100 ° C and 800 ° C. Can be used in furnaces, plastics, steel and other high temperature equipment;

(3) Corrosion-resistant bearings: The materials themselves have corrosion-resistant properties and can be applied in fields such as strong acids, alkalis, inorganics, organic salts, seawater, etc., such as electroplating equipment, electronic equipment, chemical machinery, shipbuilding, medical equipment, etc. .

(4) Anti-magnetic bearing: Because it is non-magnetic, it does not absorb dust, which can reduce the surface of the bearing to peel off, thus reducing the running noise. Can be used in demagnetization equipment. Precision instruments and other fields.

(5), electrically insulated bearings: due to high resistivity, can avoid arc damage bearings, can be used in a variety of electrical equipment requiring insulation.

(6), vacuum bearing: due to the unique oil-free self-lubricating properties of ceramic materials, in the ultra-high vacuum environment, it can overcome the problem that ordinary bearings can not achieve lubrication. Note: For the above five types of bearings, the same set of bearings can be applied to high temperature, high speed, acid and alkali, magnetic field, non-insulation, but the material properties are different (please refer to the rare earth ceramic material performance table), so when customers choose products, Choose the most suitable ceramic bearing for your application, depending on the application you are using.

Data Sheet↓

Color: Customized Density: 6.0g/cm3 Zirconia Content: 94.4% Gas permeability: 0 Water Absorption: 0 Crystal Size: 0.5um Rockwell Hardness(45N): 78R45N Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²) Flexural Strength(20°C): 800Mpa Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Fracture Toughness(20°C): 9.0 MPam1/2 Thermal Conductivity(20°C-400°C): 2.5W(m.K) Thermal Expansion Coefficient: 9.6 10-6/°C Thermal Shock Resistance: 250 △T°C

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, Ceramic Shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.