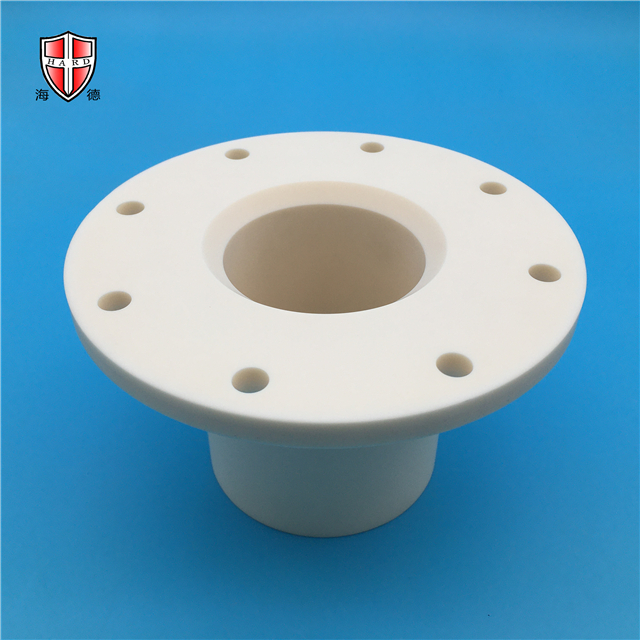

anodic zincous metallized 95 Alumina Ceramic insulating tube

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

99.7% alumina ceramic plastic ABS can also be said to be a modification of polystyrene. It has higher impact strength and better mechanical strength than HIPS, and has good processing properties. It can be used for plastics such as injection molding machines and extruders. The molding equipment performs injection molding, extrusion, blow molding, calendering, lamination, foaming, thermoforming, and can also be welded, coated, electroplated and mechanically processed. The water absorption of ABS is relatively high. It needs to be dried before processing. The drying temperature is 70~85℃ and the drying time is 2~6h. ABS products are prone to internal stress during processing. If the stress is too large, the product will crack. For annealing treatment, put the parts in a 70-80℃ hot air circulating drying box for 2 to 4 hours, and then cool to room temperature. Plastic ABS produces pipes, plates, sheets, and profiles and other products. Pipes can be used for various water pipes, air pipes, lubricants and fuel oil delivery pipes; plates and sheets can be used for floors, furniture, pools, filters, walls Interlayer and thermoforming or vacuum forming. The screw length to diameter ratio of the extruder is usually relatively high, L/D is between 18-22, and the compression ratio is (2.5-3.0). Gradual screw with torpedo head is suitable. The temperature of the barrel is 150~160°C in the hopper, 180~190°C in the front of the barrel, 185~195°C in die head, 180~200°C in mold temperature, and blow molding The temperature can be controlled between 140~180℃.

properties: High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/Ivory Density: 3.9g/cm3 Alumina Content: 96% 99% 99.5% Gas permeability: 0 Water Absorption: 0 MONS' Hardness: 82 Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²) Flexural Strength(20°C): 330Mpa Compressive Strength(20°C): 2000Mpa Fracture Toughness (20°C): 4 MPam1/2 Thermal Conductivity(20°C): 27.5W(m.K) Thermal Expansion Coefficient: 7.6 10-6/°C Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Application industry: Machinery, electronic, chemical, petroleum etc. Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.