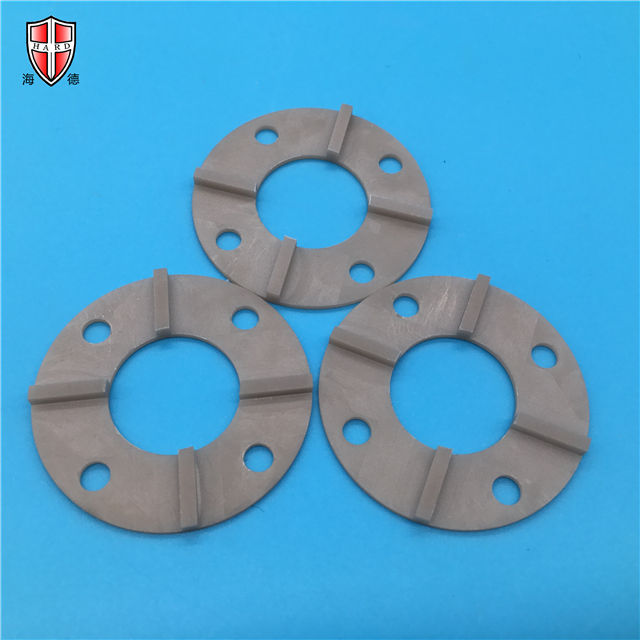

customized industrial AIN Alumina Ceramic heat sink ring plate

Reputation depends on quality, quality comes from Hard!

Aluninum Nitride Ceramic:

Aluminum nitride, a covalent bond compound, is an atomic crystal, belonging to diamond-like nitride, hexagonal crystal system, wurtzite crystal structure, non-toxic, white or off-white. AlN can be stabilized up to 2200℃. The room temperature strength is high, and the strength decreases slowly with the increase of temperature. It has good thermal conductivity and low thermal expansion coefficient, making it a good thermal shock material. It has strong resistance to molten metal corrosion and is an ideal crucible material for melting and casting pure iron, aluminum or aluminum alloy. Aluminum nitride is also an electrical insulator with good dielectric properties, and it is also very promising as an electrical component. The aluminum nitride coating on the surface of gallium arsenide can protect it from ion implantation during annealing. Aluminum nitride is also a catalyst for the transformation from hexagonal boron nitride to cubic boron nitride. It reacts slowly with water at room temperature. It can be synthesized from aluminum powder at 800~1000℃ in ammonia or nitrogen atmosphere. The product is white to gray-blue powder. Or synthesized by the Al2O3-C-N2 system at 1600~1750℃, the product is off-white powder. Or aluminum chloride and ammonia are prepared by gas phase reaction. The coating can be synthesized by vapor deposition method in AlCl3-NH3 system [1]. Aluminum nitride was first synthesized in 1877. By the 1980s, because aluminum nitride was a ceramic insulator (polycrystalline material was 70-210 W‧m−1‧K-1, and single crystal could be as high as 275 W‧m−1‧K−1), the nitrogen Aluminum has high heat transfer ability, so that aluminum nitride is widely used in microelectronics. Unlike beryllium oxide, aluminum nitride is non-toxic. Aluminum nitride is treated with metal, which can replace alumina and beryllium oxide in a large number of electronic instruments. Aluminum nitride can be prepared by reducing aluminum oxide and carbon or directly nitriding metal aluminum. From heat sinks to semiconductor processing, our Aluminum Nitride Plates and Shafts provide reliable performance and durability in demanding environments. Aluminum nitride is a substance connected by covalent bonds. It has a hexagonal crystal structure, the same shape as zinc sulfide and wurtzite.

Aluminum nitride has high hardness and exceeds traditional alumina. It is a new type of wear-resistant ceramic material, but it can only be used for severely worn parts due to its high cost.

Using AIN ceramics for heat resistance, melt erosion and thermal shock resistance, GaAs crystal crucible, Al evaporating dish, magnetic fluid power generation device and high temperature turbine corrosion resistant parts can be fabricated, and its optical properties can be used as an infrared window. The aluminum nitride film can be made into a high frequency piezoelectric element, a very large scale integrated circuit substrate, or the like.

Aluminum nitride heat-resistant, resistant to molten metal erosion, stable to acid, but easy to be eroded in alkaline solution. The AIN fresh surface is exposed to moist air and reacts to form a very thin oxide film. By utilizing this property, it can be used as a crucible and a die-casting mold material for smelting metals such as aluminum, copper, silver, and lead. AIN ceramics have good metallization properties and can be widely used in the electronics industry as an alternative to toxic cerium oxide.

Data Sheet:

Ø (1) high thermal conductivity (about 320W / m · K), close to BeO and SiC, more than 5 times that of Al2O3;

Ø(2) The thermal expansion coefficient (4.5×10-6°C) is matched with Si (3.5-4×10-6°C) and GaAs (6×10-6°C);

Ø (3) excellent electrical properties (dielectric constant, dielectric loss, volume resistivity, dielectric strength);

Ø(4) good mechanical properties, higher flexural strength than Al2O3 and BeO ceramics, can be sintered at normal pressure;

Ø (5) good optical transmission characteristics;

Ø(6) non-toxic;

Application industry:

Aluminum nitride powder has high purity, small particle size and high activity, and is the main raw material for manufacturing high thermal conductivity Aluminum Nitride Ceramic substrate.

Aluminum nitride ceramic substrate, high thermal conductivity, low expansion coefficient, high strength, high temperature resistance, chemical corrosion resistance, high resistivity, small dielectric loss, is an ideal large-scale integrated circuit heat sink substrate and packaging materials.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.