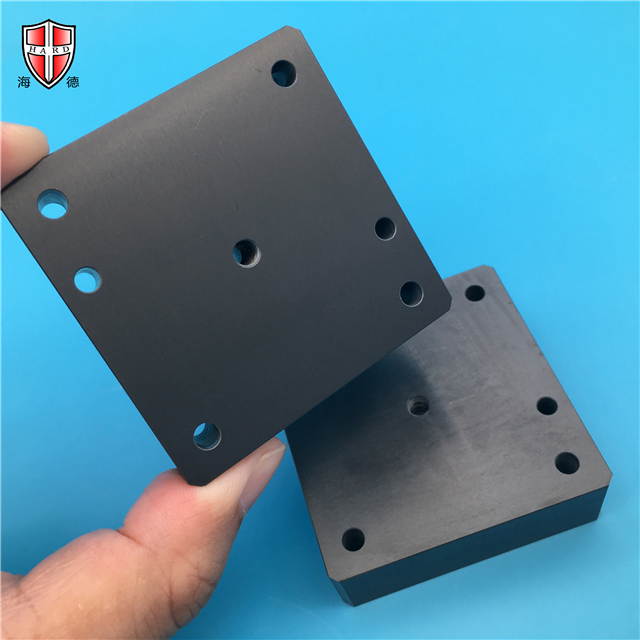

dry pressured casting Silicon Nitride Ceramic Block brick tile

Reputation depends on quality, quality comes from Hard!

Silicon Nitride Ceramic:

"The rapid biodegradation of plastics in the intestine of yellow mealworm reveals the new fate of discarding plastic waste in the environment." said Professor Yang Jun from Beijing University of Aeronautics and Astronautics. Plastics are difficult to degrade naturally in the environment, and polystyrene is the most. Due to its high molecular weight and high stability, it is generally believed that microorganisms cannot degrade polystyrene plastics. In 2015, Professor Yang Jun's research group of Beijing University of Aeronautics and Astronautics, Dr. Zhao Jiao of Shenzhen Huada Gene Company, etc. co-published two sister research papers in the authoritative journal "Environmental Science&Technology" in the field of environmental sciences, which proved the yellow mealworm (breadworm) The larvae can degrade polystyrene, the hardest plastic. The study showed that with polystyrene foam as the only food source, the larvae of Tenebrio molitor can survive for more than one month and finally develop into adults. The polystyrene they eat is completely degraded and mineralized into CO2 or assimilated into insect bodies. fat. This discovery provides ideas for solving the global plastic pollution problem. The pollution of plastic waste produced by petrochemical industry is a world environmental problem. Most plastics are discarded after one-time consumption. So far, academic circles believe that plastic products may not be decomposed in the natural environment for tens to hundreds of years due to their stable physical and chemical structure. Professor Yang Jun introduced that in 2013, the global consumption of 299 million tons of plastics, of which polystyrene plastics accounted for 7%, consumes about 21 million tons per year. Common plastic lunch boxes, coffee cups and Other Materials that can withstand boiling water temperature are polystyrene . Authoritative investigations have shown that in the microbial community of soil, sludge, decaying garbage, or manure, polystyrene, such as plastic, only degrades in the range of 0.01%-3% in 4 months.

properties:

High hardness, high strength, wear resistance, corrosion resistance, high temperature(1200°), good thermal diffusivity, good thermal shock resistance(avoid the temperature changing rapidly), good insulativity, low density. The comprehensive properties are best in most of structure ceramic.

Data Sheet↓

Color: Black Grey

Density: >3.2g/cm3

Hardness: HRA90

Vickers Hardness (Hv50): >1550 HV0.5

Modulus of Elasticity: 290Gpa

Flexural Strength: >600Mpa

Compressive Strength: 2500Mpa

Modulus of Elasticity(25°C): 65Gpa

Fracture toughness:>6.0 Mpam1/2

Maximum Use Temperature: 1200°C

Thermal Conductivity:15-20 W(m.K)

Thermal Expansion Coefficient: >3.1 10-6/°C

Thermal Shock Resistance: 500 △T°C

Special Heat Capacity: 700 KJ/kg.K

Dielectric Strength: 1 KV/mm

Dielectric Constant: er

Volume Resistivity(20°C): 1.0*10(12)Ω.cm

Application industry:

Machinery, electronic, semiconductor, chemical, petroleum, smelt.

Specific application:

Welding shaft, electronic substrate, plunger, nozzle, slide guide, diesel parts, metal molding, shaft wheels etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.