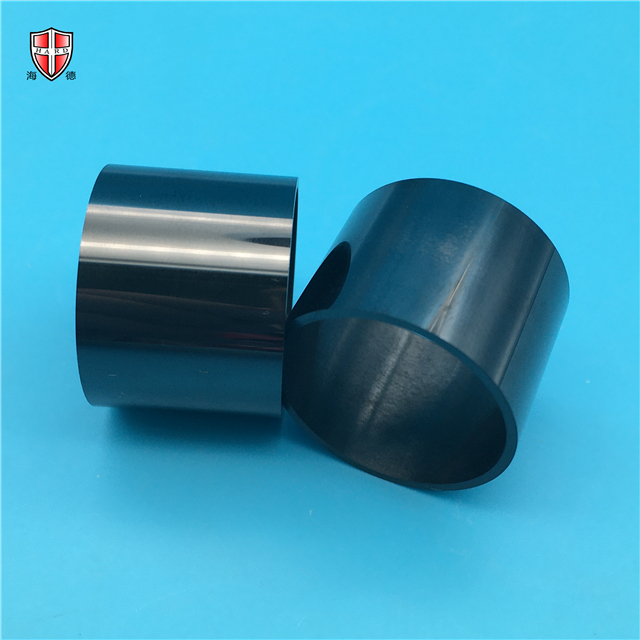

shining surface Silicon Nitride Ceramic Tube bush sleeve

Reputation depends on quality, quality comes from Hard!

Silicon Nitride Ceramic:

Magnesium alloy is a metal with high specific strength, good rigidity, and strong electromagnetic interface protection performance. Its application prospects in electronics, automobiles and other industries are very promising, and it has a tendency to replace traditional iron alloys, aluminum alloys, and even plastic materials. At present, the magnesium alloy parts used in automobiles include instrument panels, seat frames, engine covers, etc. Magnesium alloy pipe parts are also widely used in cutting-edge industrial fields such as airplanes, missiles, and spacecraft. However, the close-packed hexagonal lattice structure of magnesium alloy determines that it cannot be stamped and formed at room temperature. Now people have developed a mold that combines heating and forming to stamp and form magnesium alloy products. The product forming process is as follows: during the lowering of the punch slide, the upper die and the lower die are clamped to heat the material, and then the material is formed in an appropriate motion mode. This method is also suitable for the connection of molded products and the composite molding of various products in a press. Many difficult-to-form materials, such as magnesium alloys, titanium alloys and other products, can be stamped and formed by this method. Because this kind of punching requires the punch slider to have a pause function during the descending process, in order to provide time for heating the material, a new concept of punching machine --- CNC crankshaft servo motor punching machine was developed, which can also be used in punching Compound processing including tapping, riveting and other processes is realized in the mold, which greatly expands the range of stamping processing and lays a solid foundation for the wide application of magnesium alloys in the plastic processing industry.

properties:

High hardness, high strength, wear resistance, corrosion resistance, high temperature(1200°), good thermal diffusivity, good thermal shock resistance(avoid the temperature changing rapidly), good insulativity, low density. The comprehensive properties are best in most of structure ceramic.

Data Sheet↓

Color: Black Grey

Density: >3.2g/cm3

Hardness: HRA90

Vickers Hardness (Hv50): >1550 HV0.5

Modulus of Elasticity: 290Gpa

Flexural Strength: >600Mpa

Compressive Strength: 2500Mpa

Modulus of Elasticity(25°C): 65Gpa

Fracture toughness:>6.0 Mpam1/2

Maximum Use Temperature: 1200°C

Thermal Conductivity:15-20 W(m.K)

Thermal Expansion Coefficient: >3.1 10-6/°C

Thermal Shock Resistance: 500 △T°C

Special Heat Capacity: 700 KJ/kg.K

Dielectric Strength: 1 KV/mm

Dielectric Constant: er

Volume Resistivity(20°C): 1.0*10(12)Ω.cm

Application industry:

Machinery, electronic, semiconductor, chemical, petroleum, smelt.

Specific application:

Welding shaft, electronic substrate, plunger, nozzle, slide guide, diesel parts, metal molding, shaft wheels etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.