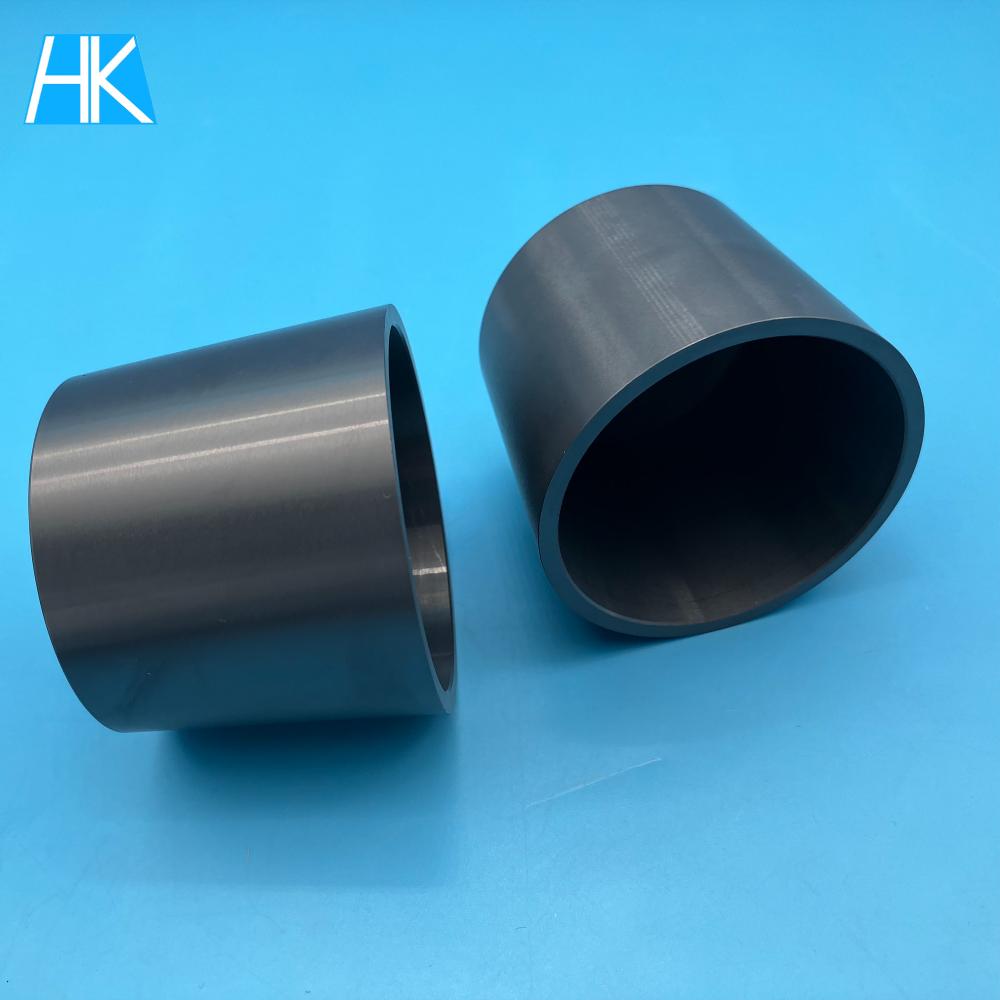

gas sintering Silicon Nitride ceramic crucible cup lid

Reputation depends on quality, quality comes from Hard!

Silicon Nitride Ceramics:

The term silicon nitride is derived from the ancient Roman word alumen (alum). In 1746, German J.H. Pott made an oxide from alum, namely alumina. In the 18th century, French Lavoisier (A.L. Lavoisier) believed that this was an oxide of an unknown metal. Its affinity with oxygen was so great that it was impossible to reduce it with carbon and other reducing agents known at the time. In 1807, the British H. Davy tried to electrolyze molten alumina to obtain metal, but failed. In 1809, he named this imaginary metal alumium, which was later changed to aluminum. In 1825, the Danish H.C. Oersted used potassium amalgam to reduce anhydrous aluminum chloride and obtained several milligrams of metallic aluminum for the first time, pointing out that it has the same color and luster as tin. In 1827, F.Whler, Germany, used potassium to reduce anhydrous aluminum chloride to obtain a small amount of metal powder. In 1845, he used aluminum chloride gas to pass through the surface of molten metal potassium, and obtained some aluminum beads, each weighing about 10-15 mg, thus making a preliminary determination of the density and ductility of aluminum, and pointed out that the melting point of aluminum is not high. In 1854, S.C. Deville, France, used sodium instead of potassium to reduce NaAlCl4 complex salt to produce metallic aluminum. The factory was built in the same year, and some aluminum helmets, tableware and toys were produced. At that time, the price of aluminum was close to that of gold. In 1886, American Hall (C.M.Hall) and France (P.L.T.Héroult) almost simultaneously obtained patents for producing metal aluminum by cryolite-alumina molten salt electrolysis. In 1888, the first electrolytic aluminum plant was established in Pittsburgh, USA, and aluminum production has entered a new stage. In 1956, the world's aluminum output began to surpass that of copper and ranked first among non-ferrous metals. The price of aluminum is relatively cheap in terms of volume among commonly used non-ferrous metals.

properties:

High hardness, high strength, wear resistance, corrosion resistance, high temperature(1200°), good thermal diffusivity, good thermal shock resistance(avoid the temperature changing rapidly), good insulativity, low density. The comprehensive properties are best in most of structure ceramic.

Data Sheet↓

Color: Black Grey

Density: >3.2g/cm3

Hardness: HRA90

Vickers Hardness (Hv50): >1550 HV0.5

Modulus of Elasticity: 290Gpa

Flexural Strength: >600Mpa

Compressive Strength: 2500Mpa

Modulus of Elasticity(25°C): 65Gpa

Fracture toughness:>6.0 Mpam1/2

Maximum Use Temperature: 1200°C

Thermal Conductivity:15-20 W(m.K)

Thermal Expansion Coefficient: >3.1 10-6/°C

Thermal Shock Resistance: 500 △T°C

Special Heat Capacity: 700 KJ/kg.K

Dielectric Strength: 1 KV/mm

Dielectric Constant: er

Volume Resistivity(20°C): 1.0*10(12)Ω.cm

Application industry:

Machinery, electronic, semiconductor, chemical, petroleum, smelt.

Specific application:

Welding shaft, electronic substrate, Ceramic Plunger, nozzle, slide guide, diesel parts, metal molding, shaft wheels etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.