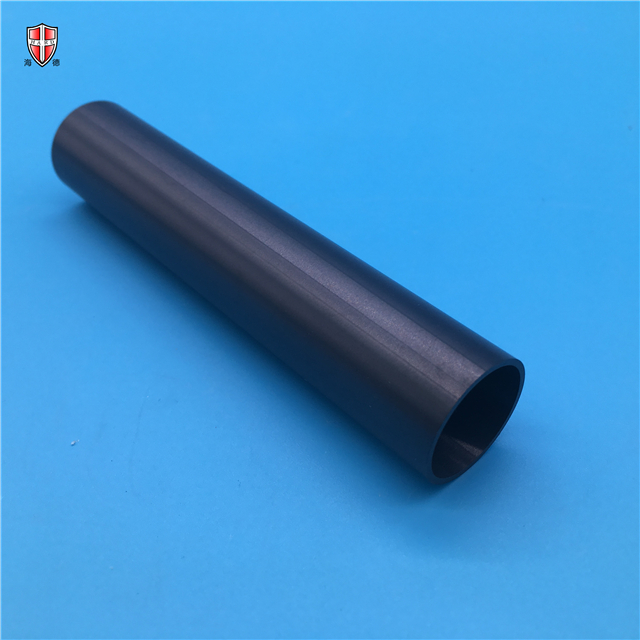

black grey insulated Silicon Nitride Ceramic Bushing pipe

Reputation depends on quality, quality comes from Hard!

Silicon Nitride Ceramic:

1) Fabrication of components on thermal equipment such as crucibles, muffle furnaces, burners, heating fixtures, molds, aluminum conduits, thermocouple protection sleeves, aluminum electrolytic cell linings, etc. in the metallurgical industry.

(2) Production of high-speed turning tools, bearings, heat-treated supports for metal parts, rotor engine blades, gas turbine guide vanes and turbine blades in the mechanical manufacturing industry.

(3) Used in the chemical industry as ball valves, pump bodies, seal rings, filters, heat exchanger components and immobilized catalyst carriers, combustion boats, and evaporating dishes.

(4) In the semiconductor, aerospace, atomic energy industries, etc. used in the manufacture of switch circuit substrates, film capacitors, electrical insulators subject to high temperature or temperature changes, radar wire covers, missile tail nozzles, support members and spacers in atomic reactors, A carrier of nuclear fission material.

(5) Artificial joints can be used in the pharmaceutical industry.

The reaction-sintered silicon nitride is formed by forming a mixture of Si powder or Si powder and Si3N4 powder, pre-nitriding by nitrogen gas at about 1200 °C, and then mechanically processing into a desired piece, and finally performing final nitriding sintering at about 1400 °C. In this process, it is not necessary to add a sintering aid or the like, so the strength of the material at a high temperature is not significantly lowered. At the same time, the reaction-sintered silicon nitride has non-shrinkage characteristics, and can prepare components with complicated shapes. However, due to the low density of the product, the density is 70% to 90%, and a large number of pores exist, and the mechanical properties are greatly affected.

properties:

High hardness, high strength, wear resistance, corrosion resistance, high temperature(1200°), good thermal diffusivity, good thermal shock resistance(avoid the temperature changing rapidly), good insulativity, low density. The comprehensive properties are best in most of structure ceramic.

Data Sheet↓

Color: Black Grey

Density: >3.2g/cm3

Hardness: HRA90

Vickers Hardness (Hv50): >1550 HV0.5

Modulus of Elasticity: 290Gpa

Flexural Strength: >600Mpa

Compressive Strength: 2500Mpa

Modulus of Elasticity(25°C): 65Gpa

Fracture toughness:>6.0 Mpam1/2

Maximum Use Temperature: 1200°C

Thermal Conductivity:15-20 W(m.K)

Thermal Expansion Coefficient: >3.1 10-6/°C

Thermal Shock Resistance: 500 △T°C

Special Heat Capacity: 700 KJ/kg.K

Dielectric Strength: 1 KV/mm

Dielectric Constant: er

Volume Resistivity(20°C): 1.0*10(12)Ω.cm

Application industry:

Machinery, electronic, semiconductor, chemical, petroleum, smelt.

Specific application:

Welding shaft, electronic substrate, plunger, nozzle, slide guide, diesel parts, metal molding, shaft wheels etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.