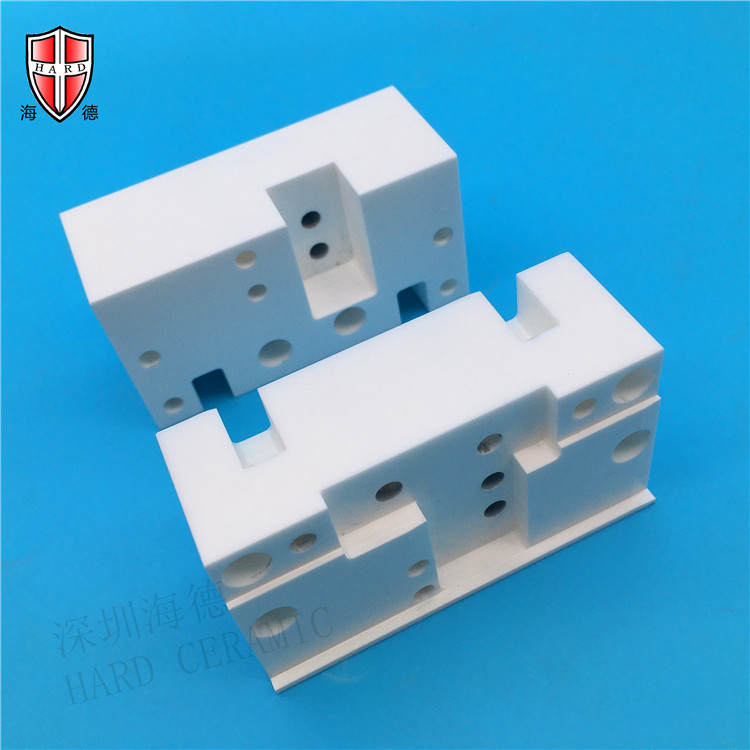

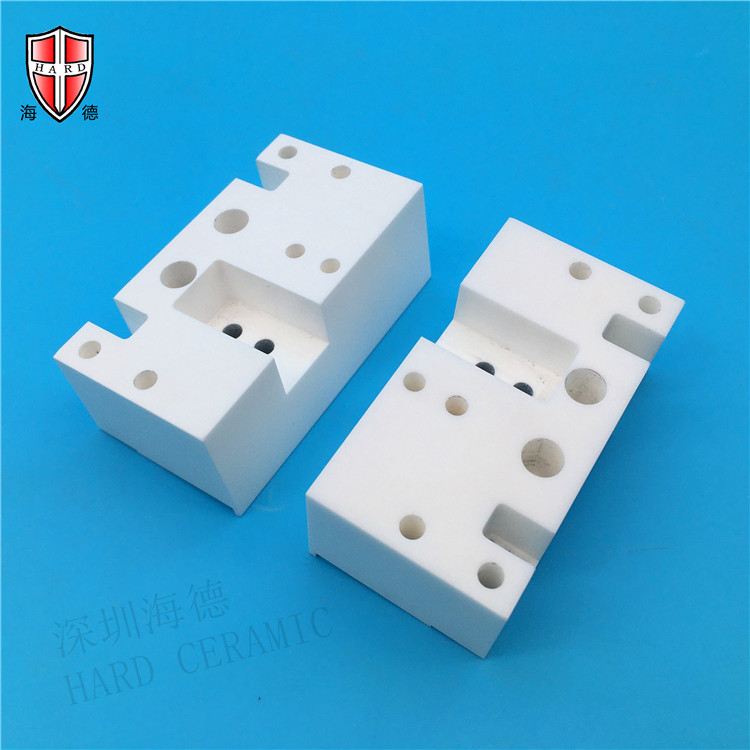

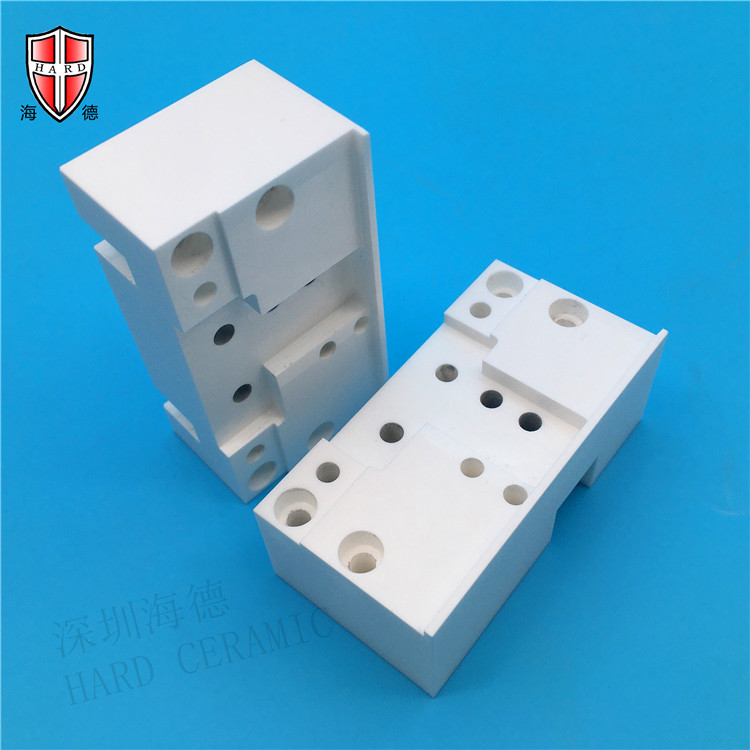

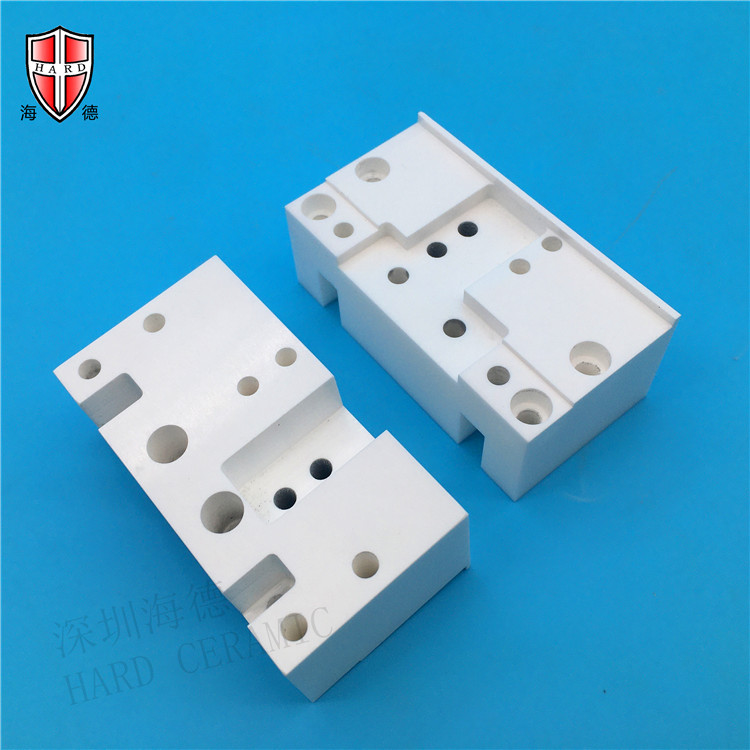

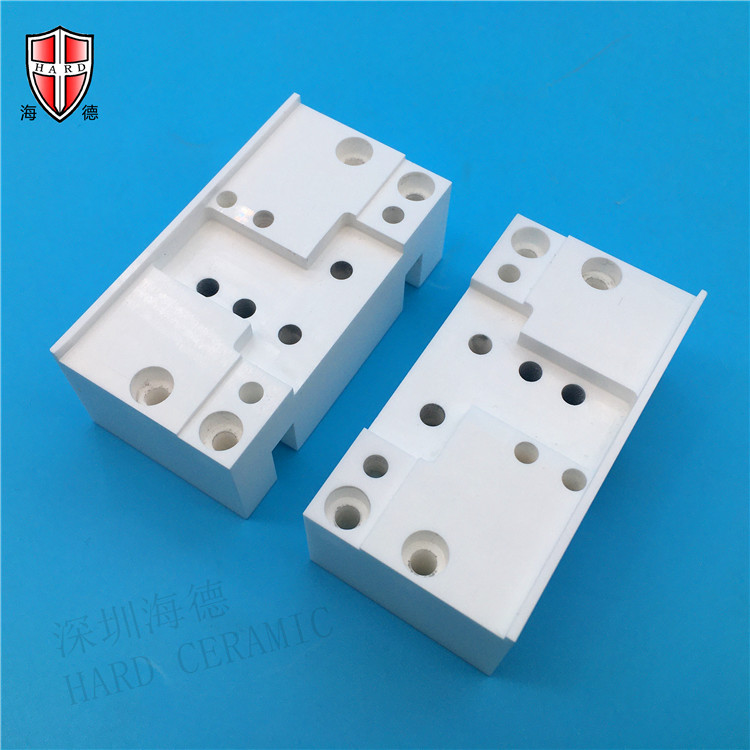

Source Zirconia Ceramic processing resistant to impact wear zirconia precision ceramics ceramic parts customized

Reputation depends on quality, quality comes from Hard!

Zirocnia Ceramics:

The zirconia numerical control part adopts MCS-51 series 8031 single-chip microcomputer to realize the main control of the whole system. Use 8031 to connect 3 pieces of 2764 (E-PROM), a piece of 6264 (RAM), a piece of 8255 (extended I/O), and a piece of 8155 chip to expand into a simpler microcomputer Macor Ceramics control system. 2764 is used as program memory, 6264 is used to expand the RAM memory of 8031, 8155 is used as keyboard and display interface, and 8255 is Silicon Nitride Parts used to receive the control signal of the multiplexer switch on the control panel. Figure 2 is a schematic diagram of the hardware structure of the control system. When the single-chip microcomputer system controls a stepping motor on the X and Y axes, the horizontal and vertical linear feed of the milling machine can be realized; when the XY axis is controlled to cooperate with the linkage, the straight line, oblique line and zirconia arc in the horizontal plane can be realized. And the processing of compound trajectory, the non-circular curve in the horizontal plane can be approximately compounded. Based on the original processing Silicon Nitride Plate functions of the milling machine, its control accuracy and processing accuracy are much higher than those of ordinary milling machines.

Two types of milling machines published by Zirconia Ceramics that cannot be used by foundries.

Data Sheet↓

Color: Customized

Density: 6.0g/cm3

Zirconia Content: 94.4%

Gas permeability: 0

Water Absorption: 0

Crystal Size: 0.5um

Rockwell Hardness(45N): 78R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 800Mpa

Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Fracture Toughness(20°C): 9.0 MPam1/2

Thermal Conductivity(20°C-400°C): 2.5W(m.K)

Thermal Expansion Coefficient: 9.6 10-6/°C

Thermal Shock Resistance: 250 △T°C

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, Ceramic Shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

Why Choose Us?

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Reputation depends on quality, quality comes from Hard!

Zirocnia Ceramics:

The zirconia numerical control part adopts MCS-51 series 8031 single-chip microcomputer to realize the main control of the whole system. Use 8031 to connect 3 pieces of 2764 (E-PROM), a piece of 6264 (RAM), a piece of 8255 (extended I/O), and a piece of 8155 chip to expand into a simpler microcomputer Macor Ceramics control system. 2764 is used as program memory, 6264 is used to expand the RAM memory of 8031, 8155 is used as keyboard and display interface, and 8255 is Silicon Nitride Parts used to receive the control signal of the multiplexer switch on the control panel. Figure 2 is a schematic diagram of the hardware structure of the control system. When the single-chip microcomputer system controls a stepping motor on the X and Y axes, the horizontal and vertical linear feed of the milling machine can be realized; when the XY axis is controlled to cooperate with the linkage, the straight line, oblique line and zirconia arc in the horizontal plane can be realized. And the processing of compound trajectory, the non-circular curve in the horizontal plane can be approximately compounded. Based on the original processing Silicon Nitride Plate functions of the milling machine, its control accuracy and processing accuracy are much higher than those of ordinary milling machines.

Two types of milling machines published by zirconia ceramics that cannot be used by foundries.

Data Sheet↓

Color: Customized Density: 6.0g/cm3 Zirconia Content: 94.4% Gas permeability: 0 Water Absorption: 0 Crystal Size: 0.5um Rockwell Hardness(45N): 78R45N Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²) Flexural Strength(20°C): 800Mpa Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Fracture Toughness(20°C): 9.0 MPam1/2 Thermal Conductivity(20°C-400°C): 2.5W(m.K) Thermal Expansion Coefficient: 9.6 10-6/°C Thermal Shock Resistance: 250 △T°C

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.