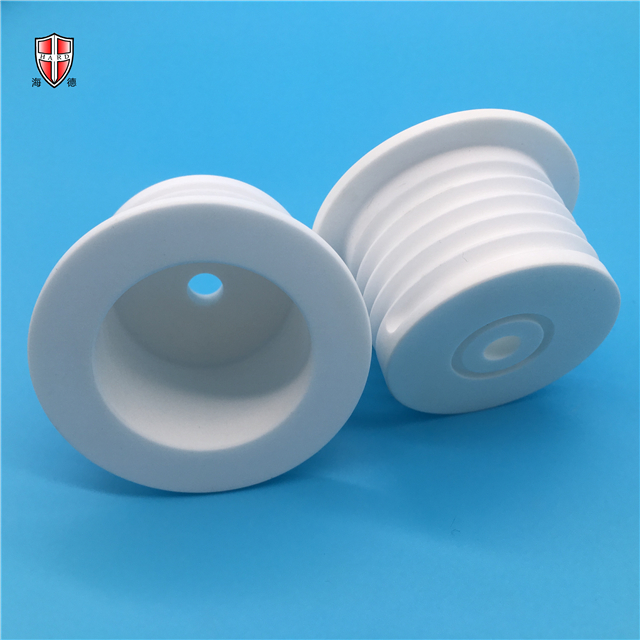

abrasive dielectric 95% Alumina Ceramic bolt cap screw

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

Al2O3 ceramics: high alumina content, compact structure and special properties, so it is called special ceramics. The Al2O3. ceramic material is a close-packed hexagonal structure composed of oxygen ions, and the aluminum ions are filled in two-thirds of the octahedral gap, which is the same stable α-Al2O3 structure as natural corundum, so the ceramic has a high melting point and high Hardness and excellent wear resistance. Ceramic patch hardness ≥ HRA85, second only to the hardness of diamond, and the surface smooth friction coefficient is small, the wear resistance is very good, especially in high temperature oxidizing medium or corrosive medium, the performance of ceramic patch material compared with other metal materials More superior.

High hardness

It has been determined by the Shanghai Institute of Ceramics of the Chinese Academy of Sciences to have a Rockwell hardness of HRA80-90, which is second only to diamond, far exceeding the wear resistance of wear-resistant steel and stainless steel.

2. Excellent wear resistance

According to the Institute of Powder Metallurgy of Central South University of Technology, its wear resistance is equivalent to 266 times that of manganese steel and 171.5 times that of high chromium cast iron. According to our customer tracking survey for more than ten years, we can extend the service life of the equipment by at least ten times under the same working conditions.

3. Light weight

Its density is 3.5g/cm3, which is only half of steel, which can greatly reduce the equipment load.

4. Wide range of applications

Any coal-fired, steel, mining, machinery, coal, mining, chemical, cement, port and other enterprises that transport coal, conveying systems, milling systems, ash discharge, dust removal systems, etc. Different types of products are selected for different needs.

properties: High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/Ivory Density: 3.9g/cm3 Alumina Content: 96% 99% 99.5% Gas permeability: 0 Water Absorption: 0 MONS' Hardness: 82 Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²) Flexural Strength(20°C): 330Mpa Compressive Strength(20°C): 2000Mpa Fracture Toughness (20°C): 4 MPam1/2 Thermal Conductivity(20°C): 27.5W(m.K) Thermal Expansion Coefficient: 7.6 10-6/°C Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Application industry: Machinery, electronic, chemical, petroleum etc. Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.