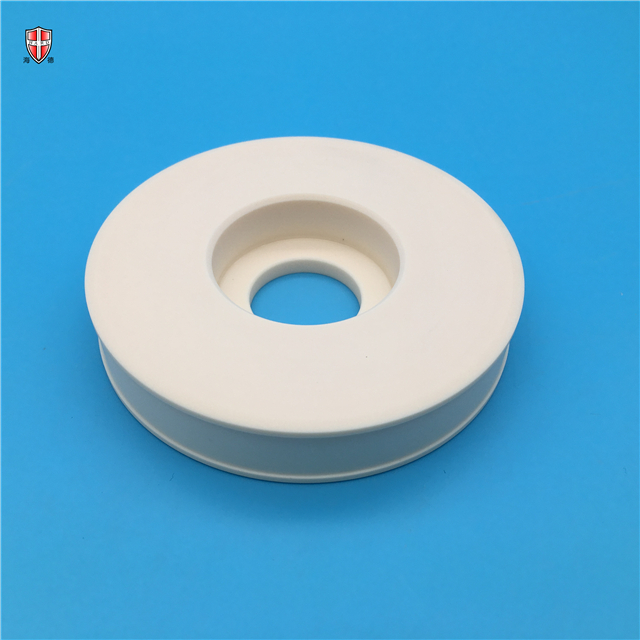

dry pressing moulding 99% Alumina Ceramic Plate

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

Silicon Nitride ceramic materials have excellent thermal stability, strong oxidation resistance and high product size. Since silicon nitride is a covalent compound with high bond strength and can form an oxide protective film in air, it also has Good chemical stability, no oxidation below 1200 °C, protective film formed at 1200~1600 °C to prevent further oxidation, and not infiltrated by many kinds of molten metals or alloys such as aluminum, lead, tin, silver, brass, nickel or Corrosion, but can be corroded by molten metal such as magnesium, nickel-chromium alloy, stainless steel, etc. In recent years, with the popularization of laser technology, laser surface treatment technology has also been used as a new surface coating treatment technology for the friction contact surface of Si3N4 ceramic bearings. The surface coating treatment, the influence of the number of grain boundary phases: the ceramics with different number of grain boundary phases were selected, and the corrosion was compared. It was found that the corrosion rate was basically consistent at the initial stage of the reaction; as the corrosion proceeded, the corrosion rate was different, and the passivation layer Appear, and the more the number of grain boundary phases, the more severe the silicon nitride corrosion is. The centrifugal grouting points into the rotating model to inject the mud, which is generated by the rotating model. Centrifugal force, accelerate the process of mud dewatering process Centrifugal grouting has the advantages of uniform thickness and compact body, but the particle size fluctuation can not be too large, otherwise there will be uneven distribution of large particles concentrated on the mold surface, resulting in uneven body, The phenomenon of inconsistent shrinkage model depends on the size of the product. Hot pressing sintering (HPS) is the pressure of Si3N4 powder and a small amount of additives (such as MgO, Al2O3, MgF2, Fe2O3, etc.) above 1916 MPa and temperatures above 1600 °C. Hot-pressed sintering of hot-pressed sintered Si3N4 ceramics used by some companies in the United Kingdom and the United States, the strength of which is up to 981 MPa or more. The addition and phase composition have a great influence on the performance of the product due to strict control of the composition of the grain boundary phase, and After the Si3N4 ceramic is sintered, proper heat treatment is performed, so that the strength (up to 490 MPa or more) can be obtained even at temperatures as high as 1300 °C.

properties: High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/Ivory Density: 3.9g/cm3 Alumina Content: 96% 99% 99.5% Gas permeability: 0 Water Absorption: 0 MONS' Hardness: 82 Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²) Flexural Strength(20°C): 330Mpa Compressive Strength(20°C): 2000Mpa Fracture Toughness (20°C): 4 MPam1/2 Thermal Conductivity(20°C): 27.5W(m.K) Thermal Expansion Coefficient: 7.6 10-6/°C Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Application industry: Machinery, electronic, chemical, petroleum etc. Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.