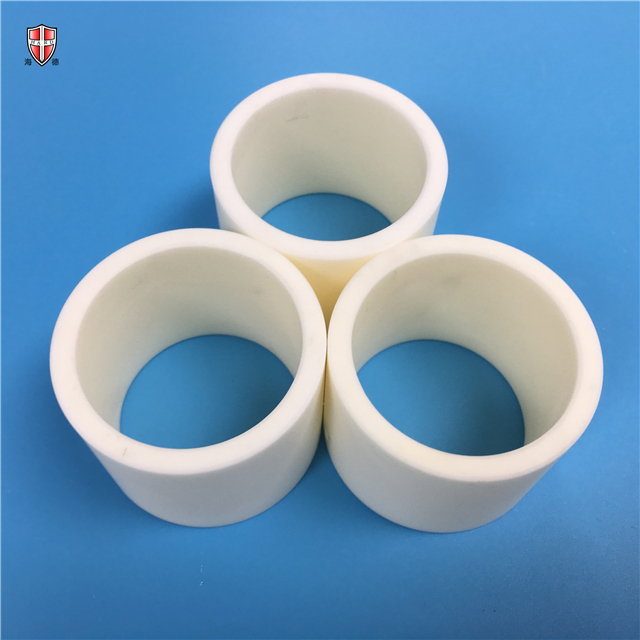

high temperacture 95% 99% Alumina Ceramic Sleeve bushing

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

Among the common ceramic and metal sealing workpieces, the more mature ceramic metallization of alumina ceramics. In applications requiring corrosion resistance, high temperature resistance and mechanical shock resistance, the mechanical strength, corrosion resistance and thermal shock resistance of alumina ceramics have certain disadvantages, such as ceramic insulated insulation pipes and ceramics at high temperature and corrosion resistance. In the field of packaging sensors, ceramic insulating materials with higher strength, higher thermal shock resistance and higher bending strength are required to replace alumina ceramics. At normal temperature, the impact toughness, flexural strength, insulation and corrosion resistance of Zirconia Ceramics are ideal materials, but zirconia ceramics will exhibit insulation with oxygen concentration imbalance when the temperature reaches 300 °C or higher. Declining characteristics. At present, Silicon Nitride Ceramics are an ideal material to replace alumina ceramics for higher requirements. Silicon Nitride ceramics have good heat resistance characteristics, and are directly decomposed at around 1870 ° C under normal pressure. The oxidizing atmosphere can be used up to 1400 ° C, and the actual mechanical strength exceeds 1200 ° C. The coefficient of thermal expansion is small (2.8-3.2)×10-6/°C; the thermal conductivity is high, it can reach 90W; the thermal shock resistance, the thermal shock from 1000°C to room temperature will not crack; the chemical property is stable, corrosion-resistant, except hydrofluoric acid It does not react with other inorganic acids. It does not react with oxygen in a dry atmosphere at 800 °C. When it exceeds 800 °C, it begins to form a silicon oxide film on the surface. As the temperature increases, the silicon oxide film gradually becomes stable, and can be stabilized at around 1000 °C. Oxygen produces a dense silicon oxide film. Can be maintained to 1400 ° C is basically stable; silicon nitride hardness, wear resistance, Mohs hardness is second only to diamond, cubic boron nitride, boron carbide, silicon carbide, anti-mechanical impact.

properties: High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/Ivory Density: 3.9g/cm3 Alumina Content: 96% 99% 99.5% Gas permeability: 0 Water Absorption: 0 MONS' Hardness: 82 Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²) Flexural Strength(20°C): 330Mpa Compressive Strength(20°C): 2000Mpa Fracture Toughness (20°C): 4 MPam1/2 Thermal Conductivity(20°C): 27.5W(m.K) Thermal Expansion Coefficient: 7.6 10-6/°C Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Application industry: Machinery, electronic, chemical, petroleum etc. Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.