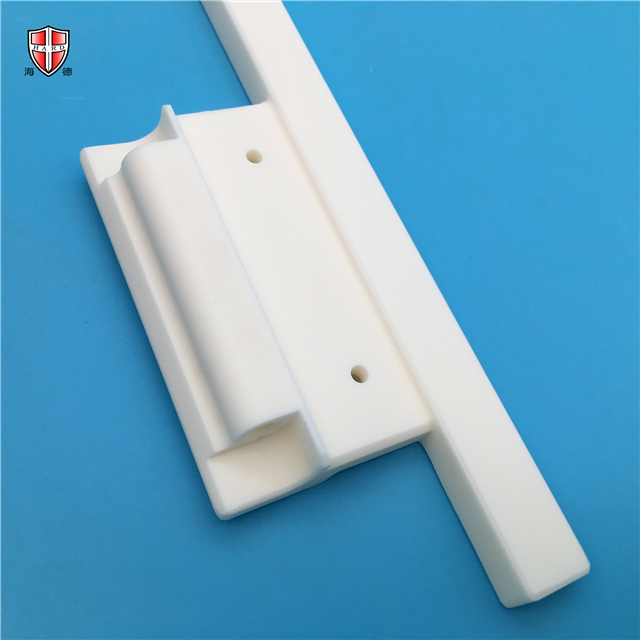

industrial engineering insulating Al2O3 Ceramic accessories

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

Material properties of Silicon Nitride ceramic riser

It is a high-temperature insoluble compound, has no melting point, strong resistance to high-temperature creep, the load softening point of reaction sintered silicon nitride without binder is above 1800 ℃, the friction coefficient of silicon nitride ceramic is small, under high temperature and high speed conditions , The increase of friction coefficient is also small, so it can ensure the normal operation of the mechanism, which is one of its outstanding advantages. The sliding friction coefficient of silicon nitride ceramic when it starts to grind reaches 1.0 to 1.5. After precision running-in, the friction coefficient is greatly increased. It drops and stays below 0.5, so Silicon Nitride Ceramics are considered to be self-lubricating materials. The ceramics sintered at high temperature are composed of many crystallites aggregated polycrystals, which inevitably exist on the grain boundaries. The atoms cannot be arranged in an orderly manner, they have a transitional nature, and the structure is relatively loose. Therefore, the grain boundary is an important channel for the rapid diffusion of atoms (ions). It is a weak part of the ceramic in the acid-base environment. The corrosion of silicon nitride ceramics in acid solution The characteristics are closely related to the number and crystallinity of grain boundary phases. Schilm [13] et al. Took six kinds of silicon nitride samples as experimental materials and used 1N sulfuric acid solution as the etching solution for corrosion. Several factors affecting the corrosion of silicon nitride ceramics were obtained (1) The effect of SiO2 content With the increase of SiO2 content in silicon nitride ceramics (22 ~ 42%), the reaction rate constant gradually decreases, and the initial corrosion rate even decreases by more than two orders of magnitude.

properties: High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/Ivory Density: 3.9g/cm3 Alumina Content: 96% 99% 99.5% Gas permeability: 0 Water Absorption: 0 MONS' Hardness: 82 Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²) Flexural Strength(20°C): 330Mpa Compressive Strength(20°C): 2000Mpa Fracture Toughness (20°C): 4 MPam1/2 Thermal Conductivity(20°C): 27.5W(m.K) Thermal Expansion Coefficient: 7.6 10-6/°C Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Application industry: Machinery, electronic, chemical, petroleum etc. Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.