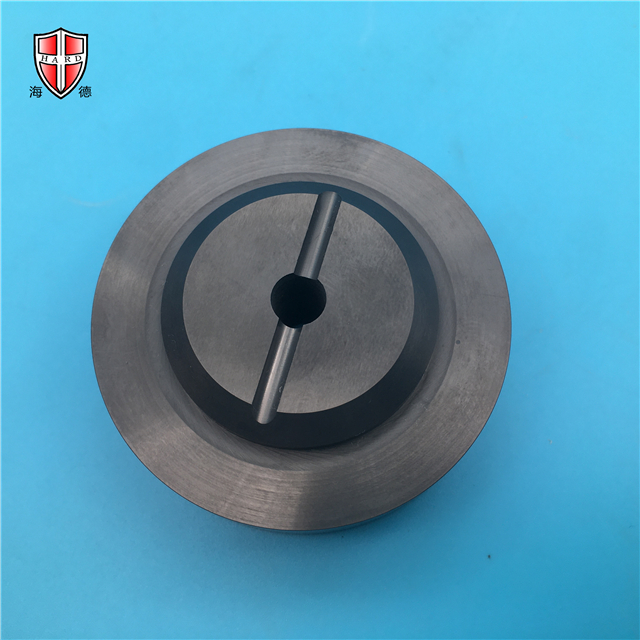

advanced Silicon Nitride Ceramic Disc roundle plate

Reputation depends on quality, quality comes from Hard!

Silicon Nitride Ceramic:

In the later period of Silicon Nitride Ceramics, aluminum was a treasure enjoyed by the emperors and nobles. The French Emperor Napoleon III used aluminum forks at banquets; the King of Thailand used aluminum bracelets. At the Paris Exposition in 1855, it was exhibited with the jewel on the crown, and the label stated "silver from clay". In 1889, Mendeleev also received vases and cups made of aluminum alloy as a gift from the Chemical Society of London. By the end of the 19th century, the price of aluminum had fallen thousands of times. First, it was because Siemens improved the generators in the 1870s to have cheap electricity; secondly, because Heroult of France and CM Hall of the United States developed the electrolysis of alumina in cryolite (Na3AlF6) in 1886, respectively. method. They were both 22 years old at the time. This pioneering work enabled large-scale production of aluminum and laid the foundation for today's industrial method of electrolytic aluminum in the world. So far, all kinds of aluminum products have been widely used in thousands of households.

On October 27, 2017, the list of carcinogens published by the International Agency for Research on Cancer of the World Health Organization was preliminarily compiled for reference, and aluminum products were included in the list of carcinogens in the first category.

On July 30, 2018, an international research team said that they had clearly detected a radioactive molecule (aluminum fluoride, the radioactive isotope of aluminum "aluminum-26") in the universe for the first time, and this molecule may be due to two reasons. Stars collided and "splashed" into interstellar space.

properties:

High hardness, high strength, wear resistance, corrosion resistance, high temperature(1200°), good thermal diffusivity, good thermal shock resistance(avoid the temperature changing rapidly), good insulativity, low density. The comprehensive properties are best in most of structure ceramic.

Data Sheet↓

Color: Black Grey

Density: >3.2g/cm3

Hardness: HRA90

Vickers Hardness (Hv50): >1550 HV0.5

Modulus of Elasticity: 290Gpa

Flexural Strength: >600Mpa

Compressive Strength: 2500Mpa

Modulus of Elasticity(25°C): 65Gpa

Fracture toughness:>6.0 Mpam1/2

Maximum Use Temperature: 1200°C

Thermal Conductivity:15-20 W(m.K)

Thermal Expansion Coefficient: >3.1 10-6/°C

Thermal Shock Resistance: 500 △T°C

Special Heat Capacity: 700 KJ/kg.K

Dielectric Strength: 1 KV/mm

Dielectric Constant: er

Volume Resistivity(20°C): 1.0*10(12)Ω.cm

Application industry:

Machinery, electronic, semiconductor, chemical, petroleum, smelt.

Specific application:

Welding shaft, electronic substrate, plunger, nozzle, slide guide, diesel parts, metal molding, shaft wheels etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.