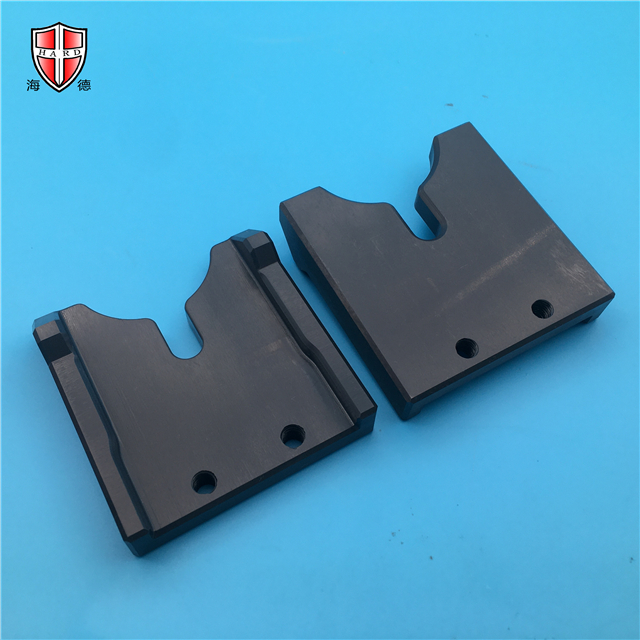

gas pressured sintered Silicon Nitride ceramic guide plate

Reputation depends on quality, quality comes from Hard!

Silicon Nitride Ceramics:

Our product line includes Silicon Nitride Ceramic Plate, silicon nitride Ceramic Chip pickers, and silicon nitride ceramic strips, which place the expanded LED chip (with or without glue) on a fixture on the stabbing table, place the LED bracket under the jig, and use a needle to stab the LED chips into the corresponding positions one by one under the microscope. Compared with automatic racking, manual thorn chips have an advantage, which is easy to replace different chips at any time, and is suitable for products that need to install multiple chips. The automatic racking actually combines the two steps of dipping (dispensing) and installing the chip. First, put silver glue (insulation glue) on the LED bracket, and then use the vacuum nozzle to suck up the LED chip to move the position, and then place it on the LED bracket. in the corresponding bracket position. In the process of automatic racking, it is mainly necessary to be familiar with the operation and programming of the equipment, and at the same time, adjust the glue and installation accuracy of the equipment. In the selection of suction nozzles, try to use bakelite suction nozzles to prevent damage to the surface of LED chips, especially blue and green chips must use bakelite. Because the steel nozzle will scratch the current spreading layer on the surface of the chip. The purpose of sintering is to solidify the silver paste, and sintering requires monitoring of temperature to prevent batch failure. The temperature of silver glue sintering is generally controlled at 150 ° C, and the sintering time is 2 hours. According to the actual situation, it can be adjusted to 170℃ for 1 hour. Insulation glue is generally 150 ℃, 1 hour. The silver glue sintering oven must be opened to replace the sintered product every 2 hours (or 1 hour) according to the process requirements, and the middle should not be opened at will. The sintering oven shall not be used for other purposes to prevent pollution.

properties:

High hardness, high strength, wear resistance, corrosion resistance, high temperature(1200°), good thermal diffusivity, good thermal shock resistance(avoid the temperature changing rapidly), good insulativity, low density. The comprehensive properties are best in most of structure ceramic.

Data Sheet↓

Color: Black Grey

Density: >3.2g/cm3

Hardness: HRA90

Vickers Hardness (Hv50): >1550 HV0.5

Modulus of Elasticity: 290Gpa

Flexural Strength: >600Mpa

Compressive Strength: 2500Mpa

Modulus of Elasticity(25°C): 65Gpa

Fracture toughness:>6.0 Mpam1/2

Maximum Use Temperature: 1200°C

Thermal Conductivity:15-20 W(m.K)

Thermal Expansion Coefficient: >3.1 10-6/°C

Thermal Shock Resistance: 500 △T°C

Special Heat Capacity: 700 KJ/kg.K

Dielectric Strength: 1 KV/mm

Dielectric Constant: er

Volume Resistivity(20°C): 1.0*10(12)Ω.cm

Application industry:

Machinery, electronic, semiconductor, chemical, petroleum, smelt.

Specific application:

Welding shaft, electronic substrate, plunger, nozzle, slide guide, diesel parts, metal molding, shaft wheels etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.