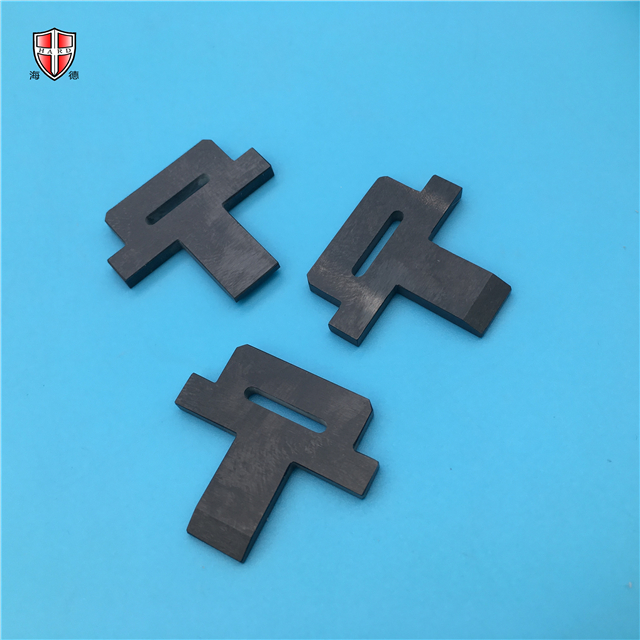

custom thermal shock resistance silicium oxide Si3N4 ceramic

Reputation depends on quality, quality comes from Hard!

Silicon Nitride Ceramic:

Spinning is a metal turning process. In the process of processing, the blank is actively rotated with the spinning die or the spinning head actively rotates around the blank and the spinning die. The spinning head makes a feed motion relative to the core mold and the blank to cause continuous local deformation of the blank to obtain the required hollow rotation Body parts.

Shaping is the second trimming of the shape of the product using the predetermined shape of the abrasive tool. Mainly reflected in the pressure plane, Wear Resistant Si3n4 Ceramic Tube Pipe Sleeve Bushing spring foot, etc. Re-processing is used when some materials have elasticity and cannot guarantee the quality of one-time molding.

Bulging is a processing method that uses a mold to stretch and thin the sheet and increase the local surface area to obtain parts. Commonly used are undulating forming, bulging of cylindrical (or tube) blanks and stretch forming of flat blanks. Bulging can be achieved by different methods, such as rigid die bulging, Wear Resistant Si3n4 Ceramic Tube Pipe Sleeve Bushing rubber bulging and hydraulic bulging.

Flanging is a plastic processing method that bends the material in the narrow band area of the edge of the sheet blank or the edge of the prefabricated hole on the blank into Wear Resistant Si3n4 Ceramic Tube Pipe Sleeve Bushing a vertical edge along a curve or a straight line. Flanging is mainly used to strengthen the edges of parts, remove trimming and make parts assembled and connected with other parts or three-dimensional parts with complex and specific shapes and reasonable spaces on the part, while improving the rigidity of the parts. When forming large sheet metal, it can also be used as a means to control cracks or wrinkles. Therefore, it is widely used in industrial sectors such as automobiles, aviation, aerospace, electronics and household appliances.

properties:

High hardness, high strength, wear resistance, corrosion resistance, high temperature(1200°), good thermal diffusivity, good thermal shock resistance(avoid the temperature changing rapidly), good insulativity, low density. The comprehensive properties are best in most of structure ceramic.

Data Sheet↓

Color: Black Grey

Density: >3.2g/cm3

Hardness: HRA90

Vickers Hardness (Hv50): >1550 HV0.5

Modulus of Elasticity: 290Gpa

Flexural Strength: >600Mpa

Compressive Strength: 2500Mpa

Modulus of Elasticity(25°C): 65Gpa

Fracture toughness:>6.0 Mpam1/2

Maximum Use Temperature: 1200°C

Thermal Conductivity:15-20 W(m.K)

Thermal Expansion Coefficient: >3.1 10-6/°C

Thermal Shock Resistance: 500 △T°C

Special Heat Capacity: 700 KJ/kg.K

Dielectric Strength: 1 KV/mm

Dielectric Constant: er

Volume Resistivity(20°C): 1.0*10(12)Ω.cm

Application industry:

Machinery, electronic, semiconductor, chemical, petroleum, smelt.

Specific application:

Welding shaft, electronic substrate, plunger, nozzle, slide guide, diesel parts, metal molding, shaft wheels etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.