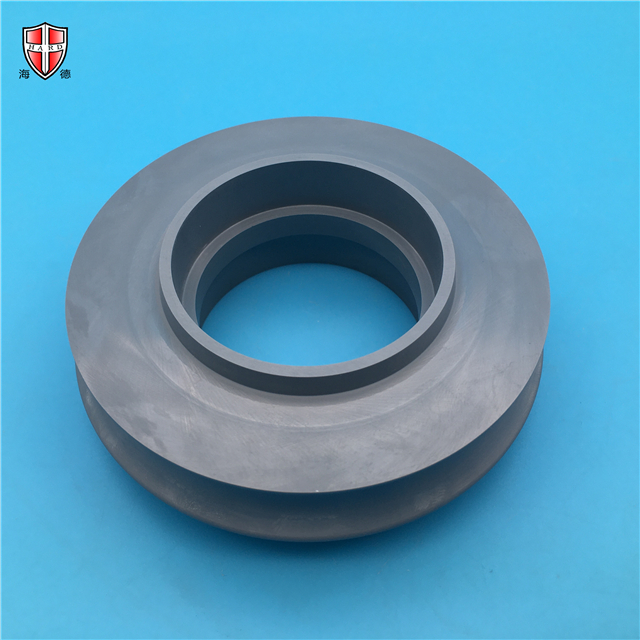

industrial machinery Silicon Nitride Ceramic Roller wheel caster

Reputation depends on quality, quality comes from Hard!

Silicon Nitride Ceramic:

Ceramics with beryllium oxide as the main component. Pure beryllium oxide (BeO) belongs to the cubic crystal system. The density is 3.03 g/㏄, the melting point is 2570℃. It has high thermal conductivity, almost equal to pure aluminum, and has good thermal shock resistance. The powder is highly toxic and makes it difficult to heal contact wounds. It is made by high temperature sintering with beryllium oxide powder as raw material, adding alumina and other ingredients. The manufacture of this ceramic requires good protective measures. The volatility of beryllium oxide in a high-temperature medium containing water vapor will increase. It will begin to volatilize at 1000°C, and the amount of volatilization will increase as the temperature rises. This brings difficulties to production, and some countries no longer produce it. The product has excellent performance, and although the price is relatively high, there is still considerable demand. Mainly used as materials for large-scale integrated circuit substrates, high-power gas laser tubes, heat sink housings for transistors, microwave output windows and neutron moderators. It is also useful for manufacturing precision glass molds in mold applications. Ⅲ. Zirconia Ceramics I. The melting point of zirconia ceramics is above 2700℃ and can withstand high temperatures of 2300℃. The recommended operating temperature is 2000℃~2200℃. Therefore, it can be used as a reactor insulation material. As an additive, zirconia can greatly improve the strength and toughness of ceramics and produce zirconia toughened ceramics (PSZ). Ⅱ. Zirconia toughened ceramics have a multi-phase structure, which can have 3 different crystal structures at different temperatures and pressures, so that under suitable conditions, stress can induce phase transformation and phase transformation toughness, which greatly improves fracture toughness . Zirconia toughened Alumina Ceramic Material has a strength of 1200 MPa and a fracture toughness of 15 MPa·m. Ⅲ. Zirconia toughened ceramics have the performance to meet the requirements of hot extrusion molds, and have the characteristics of high temperature resistance, corrosion resistance, and wear resistance, especially withstand high temperature and pressure, have less permanent deformation, and are harder than tungsten carbide, nickel-based or cobalt-based High-quality alloys are more suitable for hot extrusion dies.

properties:

High hardness, high strength, wear resistance, corrosion resistance, high temperature(1200°), good thermal diffusivity, good thermal shock resistance(avoid the temperature changing rapidly), good insulativity, low density. The comprehensive properties are best in most of structure ceramic.

Data Sheet↓

Color: Black Grey

Density: >3.2g/cm3

Hardness: HRA90

Vickers Hardness (Hv50): >1550 HV0.5

Modulus of Elasticity: 290Gpa

Flexural Strength: >600Mpa

Compressive Strength: 2500Mpa

Modulus of Elasticity(25°C): 65Gpa

Fracture toughness:>6.0 Mpam1/2

Maximum Use Temperature: 1200°C

Thermal Conductivity:15-20 W(m.K)

Thermal Expansion Coefficient: >3.1 10-6/°C

Thermal Shock Resistance: 500 △T°C

Special Heat Capacity: 700 KJ/kg.K

Dielectric Strength: 1 KV/mm

Dielectric Constant: er

Volume Resistivity(20°C): 1.0*10(12)Ω.cm

Application industry:

Machinery, electronic, semiconductor, chemical, petroleum, smelt.

Specific application:

Welding shaft, electronic substrate, plunger, nozzle, slide guide, diesel parts, metal molding, shaft wheels etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.