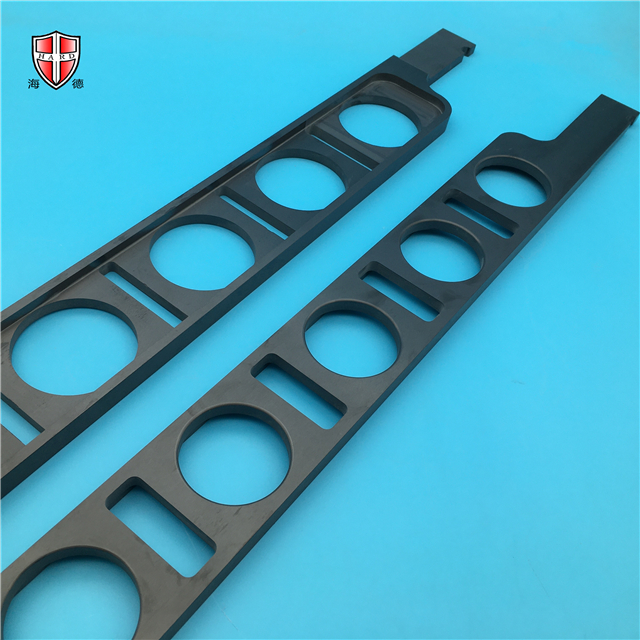

heat sink industrial Si3N4 Silicon Nitride ceramic cnc machining bars

Reputation depends on quality, quality comes from Hard!

Silicon Nitride Ceramic:

100 yellow mealworms can eat 34-39 mg of foam every day. During the 16-day test period, 47.7% of the insects ingested the foam and converted into CO2. The remaining (about 49.2%) is converted into biodegradable particles similar to rabbit feces and excreted. Tests with α-13C or β-13C labeled polystyrene plastic confirmed that it is mineralized into carbon 13 labeled carbon dioxide and lipids. The polystyrene foam in the intestine of the larvae degrades within 24 hours. The larvae that use styrofoam as their only food are as healthy as those that were fed normal food (wheat bran) after 1 month, and finally developed into beetle adults. Tenebrio molitor ate holes in the foam. After passing through the insect's intestine, the chemical structure and composition of the ingested foam change. Through the use of gel permeation chromatography (GPC), carbon 13 nuclear magnetic resonance spectroscopy, and thermogravimetric Fourier transform infrared spectroscopy, it was confirmed that the long-chain polystyrene molecules in the larval intestine were broken to form insect metabolites and excreted with feces. The experiment further successfully isolated a polystyrene-degrading bacterium, Exiguobacterium sp.YT2 (Exiguobacterium sp.YT2), which can use polystyrene as the sole carbon source for growth, from the larval intestine. This strain has been preserved in the General Microbiology Center of the China Microbial Culture Collection Management Committee and the National Gene Bank. It is the first polystyrene-degrading bacterium preserved in the culture center reported in the world.

properties:

High hardness, high strength, wear resistance, corrosion resistance, high temperature(1200°), good thermal diffusivity, good thermal shock resistance(avoid the temperature changing rapidly), good insulativity, low density. The comprehensive properties are best in most of structure ceramic.

Data Sheet↓

Color: Black Grey

Density: >3.2g/cm3

Hardness: HRA90

Vickers Hardness (Hv50): >1550 HV0.5

Modulus of Elasticity: 290Gpa

Flexural Strength: >600Mpa

Compressive Strength: 2500Mpa

Modulus of Elasticity(25°C): 65Gpa

Fracture toughness:>6.0 Mpam1/2

Maximum Use Temperature: 1200°C

Thermal Conductivity:15-20 W(m.K)

Thermal Expansion Coefficient: >3.1 10-6/°C

Thermal Shock Resistance: 500 △T°C

Special Heat Capacity: 700 KJ/kg.K

Dielectric Strength: 1 KV/mm

Dielectric Constant: er

Volume Resistivity(20°C): 1.0*10(12)Ω.cm

Application industry:

Machinery, electronic, semiconductor, chemical, petroleum, smelt.

Specific application:

Welding shaft, electronic substrate, plunger, nozzle, slide guide, diesel parts, metal molding, shaft wheels etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.