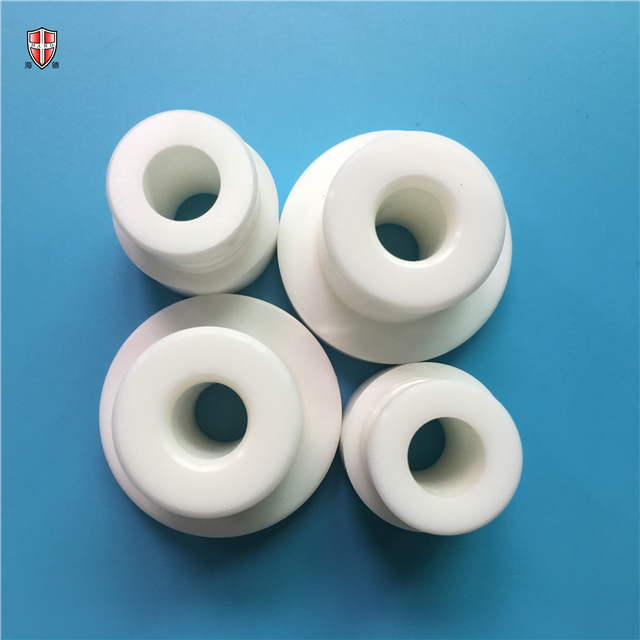

precise custom Zirconia Ceramic machined isolator

Reputation depends on quality, quality comes from Hard!

Zirocnia Ceramics:

Zirconium oxide ceramics mainly use silicon powder direct nitriding to produce Silicon Nitride powder. This traditional technology produces high content of powder impurities, high power consumption, low efficiency, and is not easy to form large-scale production. In view of this, nanotechnology experts Beginning to find a way out from the gas phase method, that is, through the high temperature gas phase reaction, one step to obtain ultrafine powder. In the gas phase method, the plasma arc gas phase synthesis technology is considered to be the current advanced technology expert identification, the design of the company There are four innovations in this production line: the plasma arc three-stage compression technology makes the diameter of the plasma beam limited to less than 10 mm, which is conducive to energy concentration. Secondly, the designed multi-component rapid synthesis device ensures multivariate The atmosphere is chemically synthesized in the plasma arc temperature zone. Thirdly, the nitrogen cooling well is designed to prevent the growth of powder particles during the gradient cooling wall collection process. Fourth, the gas-solid separation technology and electrostatic collection technology are adopted. , increasing the collection rate of nano-silicon nitride powder. The nano-silicon nitride powder prepared by using these technologies has an average particle size of 20 nm. The purity is up to 97.5%. According to reports, nano-silicon carbide, silicon carbonitride, titanium carbonitride and other powders can be produced on this production line. After several months of trial production, nanometer nitriding is produced every hour. Compared with similar products, the high efficiency of silicon powder of more than 5 kg, the production cost is greatly reduced, and the price has a strong competitive advantage.

Data Sheet↓

Color: Customized Density: 6.0g/cm3 Zirconia Content: 94.4% Gas permeability: 0 Water Absorption: 0 Crystal Size: 0.5um Rockwell Hardness(45N): 78R45N Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²) Flexural Strength(20°C): 800Mpa Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Fracture Toughness(20°C): 9.0 MPam1/2 Thermal Conductivity(20°C-400°C): 2.5W(m.K) Thermal Expansion Coefficient: 9.6 10-6/°C Thermal Shock Resistance: 250 △T°C

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, Ceramic Shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.