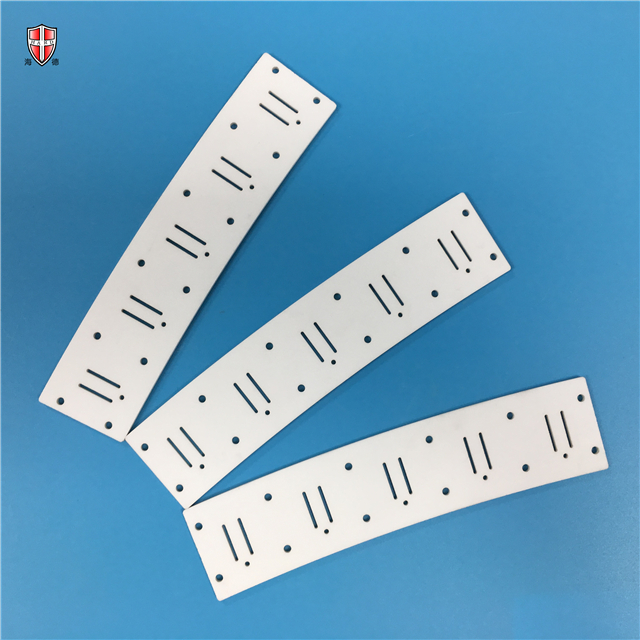

heat sink aluminum oxide ceramic substrate sheet

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

Alumina: It is one of the most widely used raw materials in boron carbide nozzle products and has a series of excellent properties. In addition, it is also an important raw material for high temperature refractories, abrasives, abrasives, laser materials and alumina gemstones. Zirconia: it is a high temperature structure boron nozzle

Alumina is one of the hard man-made materials, which has the characteristics of light weight, semiconductor physical properties, absorption of neutrons, high grinding efficiency, no reaction with strong acid and strong alkali, Mohs hardness of 9,36 and microhardness of 5400~ 6300 kg per square meter, density is 2.52 kg per square meter, melting point is 2450 degrees Celsius, boron carbide is hexagonal dark black, due to the above characteristics and properties, boron carbide is widely used in machinery, metallurgy, chemical, aerospace military and other fields. Abrasives can be used to process gemstones, ceramics, knives, bearings, and refractory materials for use in various fields of metallurgy. Densified boron carbide can be used as nozzles, mechanical seals, and ballistic resistant materials due to the greater heat of boron carbide. The neutron capture cross section, which absorbs a large amount of neutrons, can be used in high-tech fields such as nuclear reactors. As a new type of material, engineering ceramics is widely used in chemical, mechanical, electronic, information, aerospace due to its high melting point, high hardness, high modulus of elasticity, strong wear resistance and good self-lubricating properties. , automotive and other industries.

Features of boron carbide products: It has the same properties as boron carbide, extremely hard and wear-resistant, does not react with acid and alkali, high temperature resistance, reactor, neutron absorption rod, bulletproof tools, etc. Boron carbide sealing ring and sand blasting nozzle can replace known hard alloy and sealing ring made of silicon carbide, Silicon Nitride, alumina, zirconia, etc.

properties: High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/Ivory Density: 3.9g/cm3 Alumina Content: 96% 99% 99.5% Gas permeability: 0 Water Absorption: 0 MONS' Hardness: 82 Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²) Flexural Strength(20°C): 330Mpa Compressive Strength(20°C): 2000Mpa Fracture Toughness (20°C): 4 MPam1/2 Thermal Conductivity(20°C): 27.5W(m.K) Thermal Expansion Coefficient: 7.6 10-6/°C Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Application industry: Machinery, electronic, chemical, petroleum etc. Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.