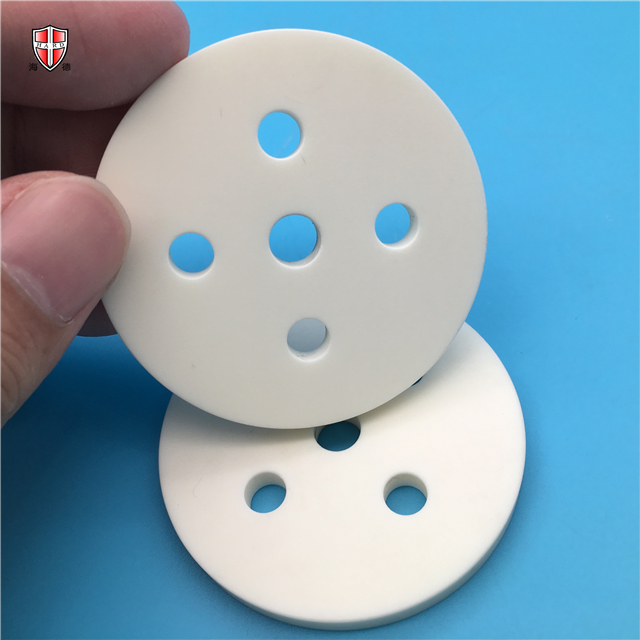

grinding milling refractory Al2O3 Ceramic burner roundel

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

The refractory powder is the matrix material of the amorphous refractory material, its grade should be higher than or equivalent to the refractory aggregate, and the fineness requirement is less than 0.09mm or 0.088mm should be greater than 85%. For ultrafine powder, 80% should be below 5mm.

In the production of amorphous refractories, the refractory materials commonly used as refractory aggregates and powders are: bauxite clinker, clay material, semi-silica material, siliceous material, magnesium material, kyanite group minerals Raw materials, mullite, industrial alumina, corundum, spinel, silicon carbide, Silicon Nitride, chromite, zircon, etc. After these refractory raw materials are destroyed and pulverized, the required raw materials for the amorphous refractories are prepared. In order to ensure the quality of the products, the raw materials must be inspected before use. The top material of the hearth is made of profiled first-grade high-aluminum material. The side walls and bottom are made of Japanese Aesop YK series material zirconium-magnesium-aluminum composite mullite lightweight heat-insulating bricks. The bottom partition beam bricks and wear-resistant rails are made of corundum. Mullite material. The thermal insulation layer is made of Japanese Isomalite poly light brick + light brick + ceramic fiber board, which has excellent heat insulation effect, small heat capacity, and energy saving and consumption reduction. 1. The equipment consists of feed horizontal push, main thruster, discharge horizontal push, longitudinal pushback, and return roller. It consists of control cabinet, manual operation station and PLC cabinet (the equipment line simulation diagram is on the panel) ) Monitor all operations. Each corresponding part is designed with safety protection alarm device (including over-pressure, time-out alarm, each action on the program is interlocked and controlled by PLC programming)

The main propulsion device adopts hydraulic propulsion, the cylinder stroke is 850mm, and it is equipped with German Rexroth precision speed regulating valve, which can realize the stepless speed regulation of the main propulsion in the range of 1500 ~ 2500mm / h. The large propulsion 8T main propulsion device has the functions of automatic conversion of forward and backward vehicles, fast forward, slow forward, and fast reverse, and the travel advancement 4. The system is equipped with manual and automatic control modes. The automatic control is controlled by a PLC programmable controller, and each action on the program is interlocked; each of the furnace head and the furnace tail is provided with a manual operation box to control the various actions of the feeding and discharging devices. An emergency stop button is provided on the operation station for emergency stop of the feeding system.

properties: High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/Ivory Density: 3.9g/cm3 Alumina Content: 96% 99% 99.5% Gas permeability: 0 Water Absorption: 0 MONS' Hardness: 82 Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²) Flexural Strength(20°C): 330Mpa Compressive Strength(20°C): 2000Mpa Fracture Toughness (20°C): 4 MPam1/2 Thermal Conductivity(20°C): 27.5W(m.K) Thermal Expansion Coefficient: 7.6 10-6/°C Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Application industry: Machinery, electronic, chemical, petroleum etc. Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.