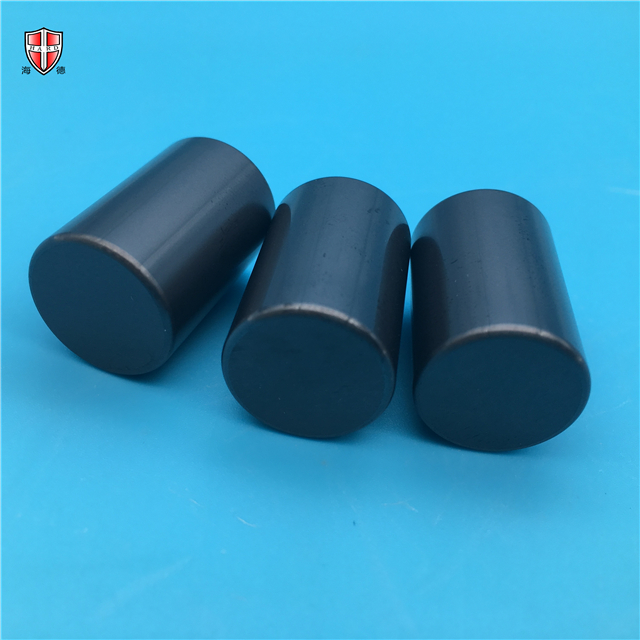

polished chamfer Silicon Nitride ceramic bearing locating pin roller

Reputation depends on quality, quality comes from Hard!

Silicon Nitride Ceramic:

Crucible is an important part of chemical instruments. It is a vessel for melting and refining liquid metal and heating and reacting between solid and liquid. It is the basis for ensuring the smooth progress of chemical reactions. The crucible has many models and specifications, and it is not restricted by the production scale, batch size and smelting material variety during application. It can be selected at will, with strong applicability, and can ensure the purity of the smelted material. Put it in a dry place after use and avoid rainwater intrusion; it must be slowly baked to 500 degrees Celsius before use. Feeding should be based on the capacity of the crucible, and avoid squeezing too tightly to avoid thermal expansion and cracking of the crucible. When taking out the molten metal, it is best to use a spoon to scoop it out, and use calipers as little as possible. If you use calipers and other tools, they should be consistent with the shape of the crucible to avoid excessive local stress and shorten the service life. The service life of the crucible is related to the usage. It should be avoided that the strong oxidizing flame is sprayed directly on the crucible, and the raw material of the crucible will be oxidized short-lived. Crucible production raw materials can be summarized into three types. One is crystalline natural graphite, the other is plastic refractory clay, and the third is calcined hard kaolin skeleton clinker. Beginning in 2008, high-temperature-resistant synthetic materials, such as silicon carbide, alumina emery and ferrosilicon, have been used as the skeleton clinker of the crucible. This clinker has a significant effect on improving the quality of crucible products, enhancing the density and mechanical strength of the crucible.

properties:

High hardness, high strength, wear resistance, corrosion resistance, high temperature(1200°), good thermal diffusivity, good thermal shock resistance(avoid the temperature changing rapidly), good insulativity, low density. The comprehensive properties are best in most of structure ceramic.

Data Sheet↓

Color: Black Grey

Density: >3.2g/cm3

Hardness: HRA90

Vickers Hardness (Hv50): >1550 HV0.5

Modulus of Elasticity: 290Gpa

Flexural Strength: >600Mpa

Compressive Strength: 2500Mpa

Modulus of Elasticity(25°C): 65Gpa

Fracture toughness:>6.0 Mpam1/2

Maximum Use Temperature: 1200°C

Thermal Conductivity:15-20 W(m.K)

Thermal Expansion Coefficient: >3.1 10-6/°C

Thermal Shock Resistance: 500 △T°C

Special Heat Capacity: 700 KJ/kg.K

Dielectric Strength: 1 KV/mm

Dielectric Constant: er

Volume Resistivity(20°C): 1.0*10(12)Ω.cm

Application industry:

Machinery, electronic, semiconductor, chemical, petroleum, smelt.

Specific application:

Welding shaft, electronic substrate, plunger, nozzle, slide guide, diesel parts, metal molding, shaft wheels etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.