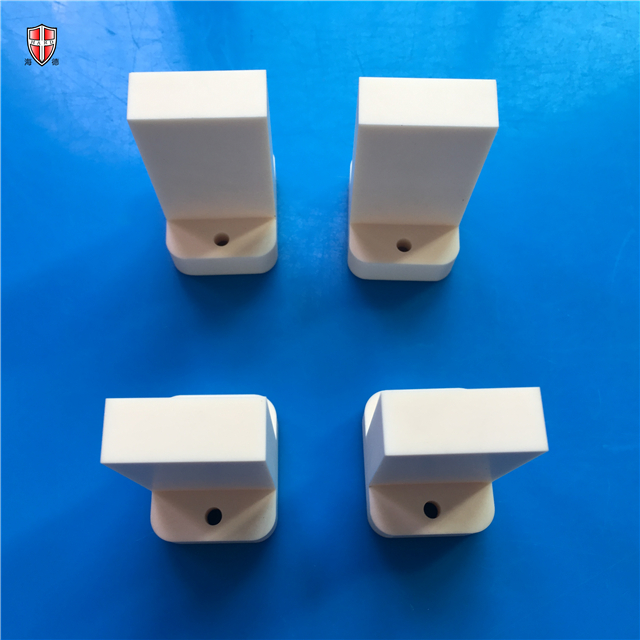

industrial alumina beige ceramic machinery parts factory

Reputation depends on quality, quality comes from Hard!

Alumina Ceramics:

Alumina ceramics is provided with an on-line surface treatment process of aluminum nitride powder. The surface of the aluminum nitride powder is waterproofed by polymer coupling agent, surface hydrolysis-resistant group grafting, macromolecular dispersant coupling and surface bridging reaction mechanism. Antioxidant treatment, successfully prepared anti-hydrolysis anti-oxidation aluminum nitride powder, in the process of air and customer use, can resist hydrolysis and anti-oxidation, greatly improve the thermal and insulating properties of aluminum nitride powder, after modification and treatment The aluminum nitride powder can be well mixed with the polymer material to form a dense heat conduction channel and an interpenetrating network, and the heat conduction and heat dissipation effects are largely exerted. Application direction of aluminum nitride 1 thermal silica gel and thermal epoxy resin, LED packaging material; 2 thermal conductive plastic PA, PPS, PE, PC application; 3 high thermal conductivity silicone rubber, fluorine rubber application; 4 applied to the electronics field and Motor industry; 5 other application areas: ultra-fine aluminum nitride powder can be used to smelt non-ferrous metals and semiconductor materials gallium arsenide bismuth, evaporation boat, thermocouple protection tube, high temperature insulation, microwave dielectric material, high temperature and resistance Corrosion structure ceramics and transparent microwave ceramic products, as well as current applications and polyimide resin, LED heat dissipation, thermal insulation mica tape, thermal grease, high thermal conductivity insulating varnish and heat transfer oil, high thermal conductivity slot insulation, high thermal conductivity impregnating resin.

properties: High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/Ivory Density: 3.9g/cm3 Alumina Content: 96% 99% 99.5% Gas permeability: 0 Water Absorption: 0 MONS' Hardness: 82 Vickers Hardness (Hv50): 15.7(1600) Gpa(Kg/mm²) Flexural Strength(20°C): 330Mpa Compressive Strength(20°C): 2000Mpa Fracture Toughness (20°C): 4 MPam1/2 Thermal Conductivity(20°C): 27.5W(m.K) Thermal Expansion Coefficient: 7.6 10-6/°C Thermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

Application industry: Machinery, electronic, chemical, petroleum etc. Specific application: Electrical ceramic substrate, plunger, sealing ring etc.

Why Choose Us? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.